![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

HSK-T is a new HSK system designed for turning on multi-task machines that are compatible with HSK-A type (ISO standard: ISO12164-1:2001).

The HSK system was developed by a consortium of 17 Japanese manufacturers and registered in ISO standard (ISO12164-3:2008) under the name HSK-T type in 2008 and JIS standard (JIS B6064-3) in 2013.

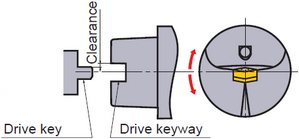

The HSK-T type has a closer tolerance between the spindle key and tool holder keyway than the HSK-A type. This results in higher cutting edge positional accuracies. For milling, the conventional HSK-A type tools can be still used.

*Note

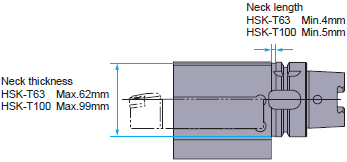

Short neck length from the flange with thick body of the HSK-T turning tool as shown in the figure at the left. Because there are machines which cannot be mounted depending on the ATC specifications of the multi-task machine(HSK-A type), please check beforehand. Also be careful of interference of the magazine with adjacent tools.

Avoid workpiece interference with improved tool accessibility.

By tilting the machines B spindle (main axis of the tool) at 45 deg, interference between the spindle, holder, workpiece and chuck can be avoided.

Improve centreline height by positioning the cutting edge at the centre of the spindle.

Increased stability and accuracy can be achieved because the cutting edge centreline height is not affected by the gap between the spindle and the key.

The double clamp mechanism offers high rigidity, accuracy and reliability that ensures secure insert clamping. There fore making it suitable turning of difficult to machine materials such as stainless and heat resistant alloys.

3 turning inserts of the same geometry can be installed on a single tool.

Larger tool holder sizes for high efficiency machining.

Technical consultation from here

24/7Contact form Japan

Japan  Japan

Japan  United States

United States  Mexico

Mexico  Brazil

Brazil  EU

EU  United Kingdom

United Kingdom  Germany

Germany  Spain

Spain  France

France  Italy

Italy  Poland

Poland  Turkey

Turkey  Czechia

Czechia  China

China  Asia Pacific

Asia Pacific  Thailand

Thailand  Vietnam

Vietnam  Indonesia

Indonesia  India

India ![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

![]() For finish cutting

For finish cutting

![]() For medium cutting

For medium cutting

![]() For rough cutting

For rough cutting