![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

Fine CBN particles increase cutting edge toughness. The high fracture resistance allows stable performance even during interrupted machining.

Optimization of the sintering conditions strengthens adhesion between fine CBN particles. This increases both fracture resistance and wear resistance.

Fracture Resistance Comparison During Interrupted Facing of High Strength Sintered Alloy

Comparison in Continuous Machining of AISI No 35 B

Technical consultation from here

24/7Contact form Japan

Japan  Japan

Japan  United States

United States  Mexico

Mexico  Brazil

Brazil  EU

EU  United Kingdom

United Kingdom  Germany

Germany  Spain

Spain  France

France  Italy

Italy  Poland

Poland  Turkey

Turkey  Czechia

Czechia  China

China  Asia Pacific

Asia Pacific  Thailand

Thailand  Vietnam

Vietnam  Indonesia

Indonesia  India

India Necessary cookies are used to help this website function properly.

For example, they provide login retention functionality.

Analytical cookies collect information about your use of this website in an anonymous and aggregated form. These cookies are used to analyze and improve the functionality of this website.

These cookies enable this website to provide enhanced functionality and personalisation. They may be set by us or by third party providers.

Functional cookies are used by social networking services to track the use of their built-in features. For example, these cookies allow you to share pages from this website with your social network.

Advertising cookies may be set through this website by our advertising partners based on the data obtained. They identify your unique browser and Internet device and may be used to provide anonymized demographic data, build profiles of your interests, and display advertising relevant to those interests.

![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

![]() For finish cutting

For finish cutting

![]() For medium cutting

For medium cutting

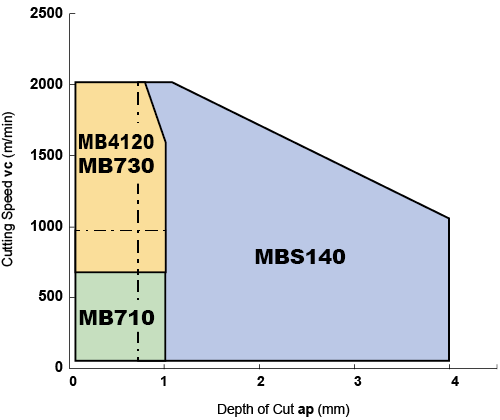

![]() For rough cutting

For rough cutting