![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

MITSUBISHI MATERIALS CORPORATION, Metalworking Solutions Company (Company President: Kazuo Ohara, Address: Marunouchi, Chiyoda-ku Tokyo) announces the launch of 86 additional items of square and corner radius end mills to the IMPACT MIRACLE series for high hardness steel machining.

They will go on sale on October 1st.

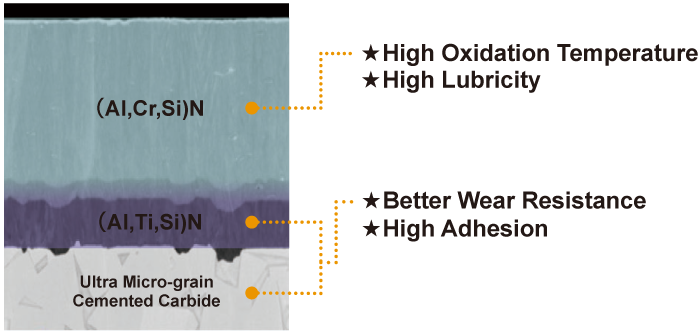

The IMPACT MIRACLE end mill series has been highly praised by many customers as end mills that offer excellent abrasion resistance, making them ideal for machining high hardness steels.

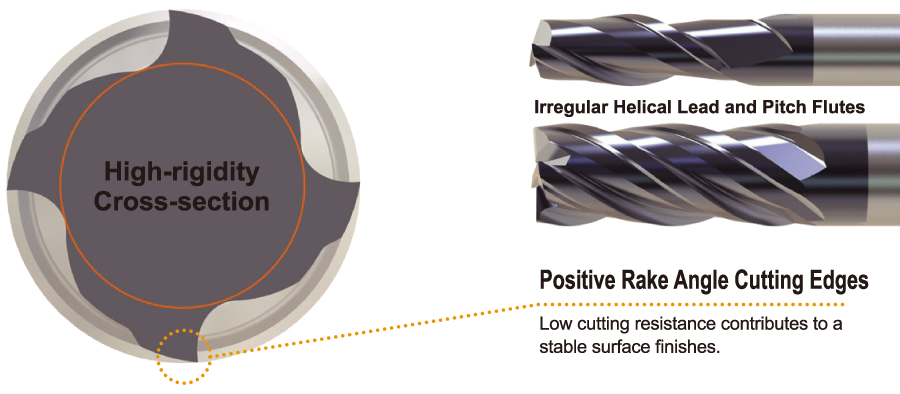

To meet the diverse machining needs of the metal cutting industry, Mitsubishi Materials announces the launch of additional 2 and 4 flute anti-vibration square corner end mills, the VFR2MV and VFR4MV types. Four and 6 flute square corner end mills, the VFRSD, VFRMD, VFRLD types, and 6-flute corner radius end mills, the VFRSDRB, and VFRMDRB types.

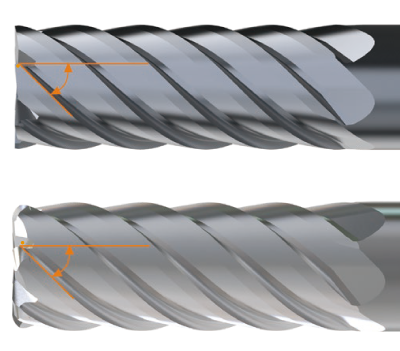

High Helix Angle 45°

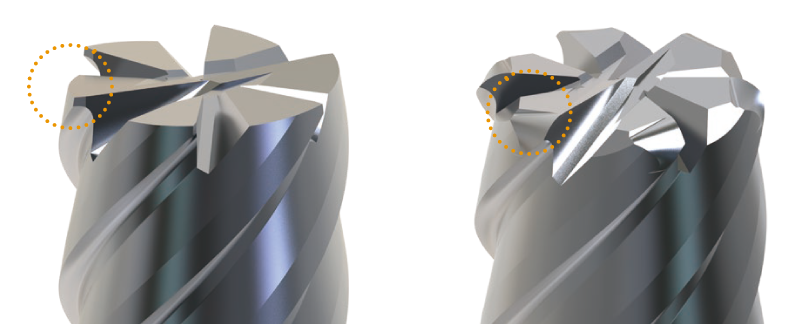

Improved sharper geometry for to high-hardness steel.

Negative Rake Angle Cutting Edges

Improved chipping resistance.