![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

Mitsubishi Materials Corporation Metalworking Solutions Company (Company President: Kazuo Ohara Address: Marunouchi, Chiyoda-ku, Tokyo) has announced that the launch of the DXAS exchangeable head type carbide drills will take place on October 1st.

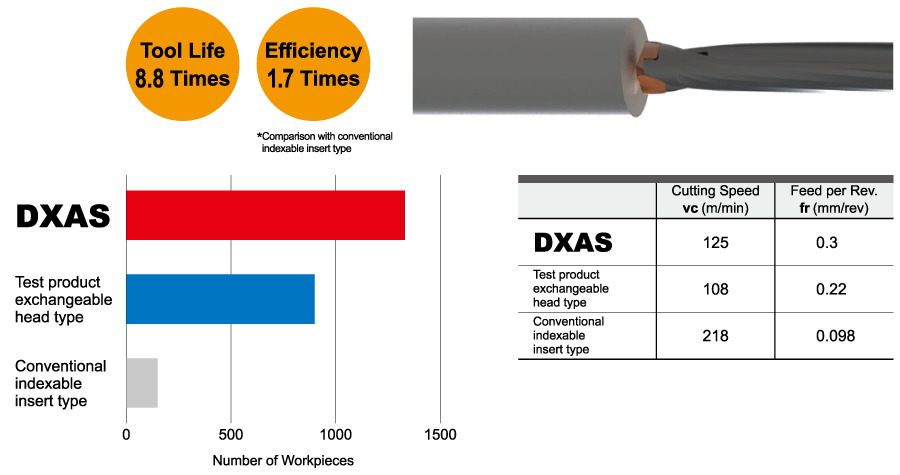

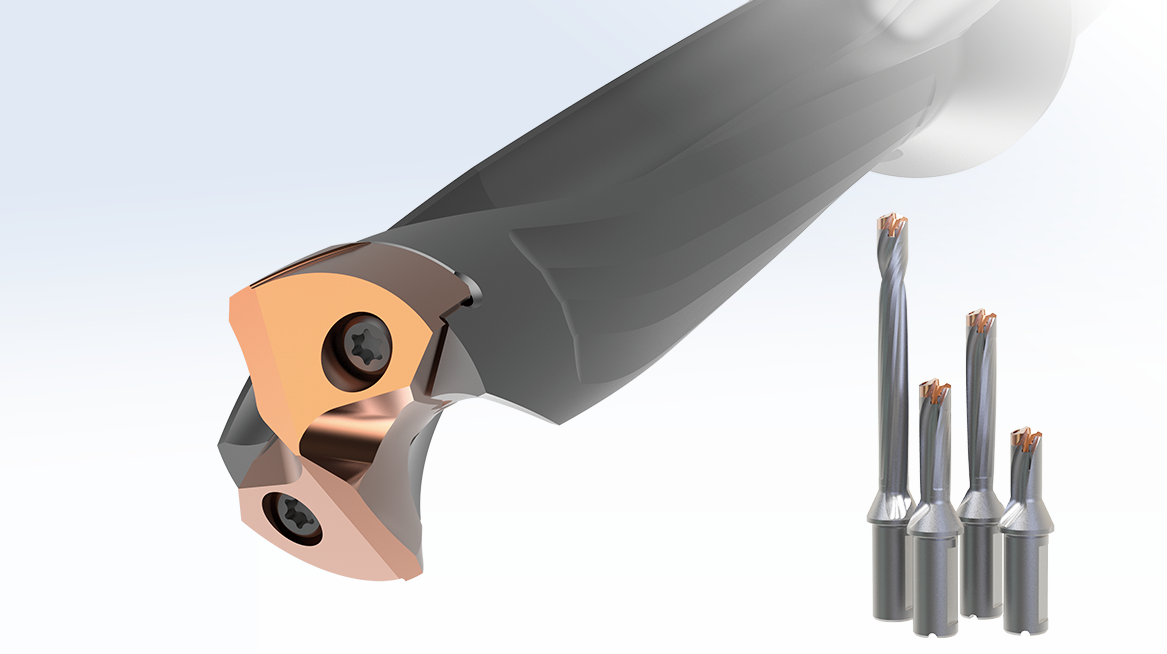

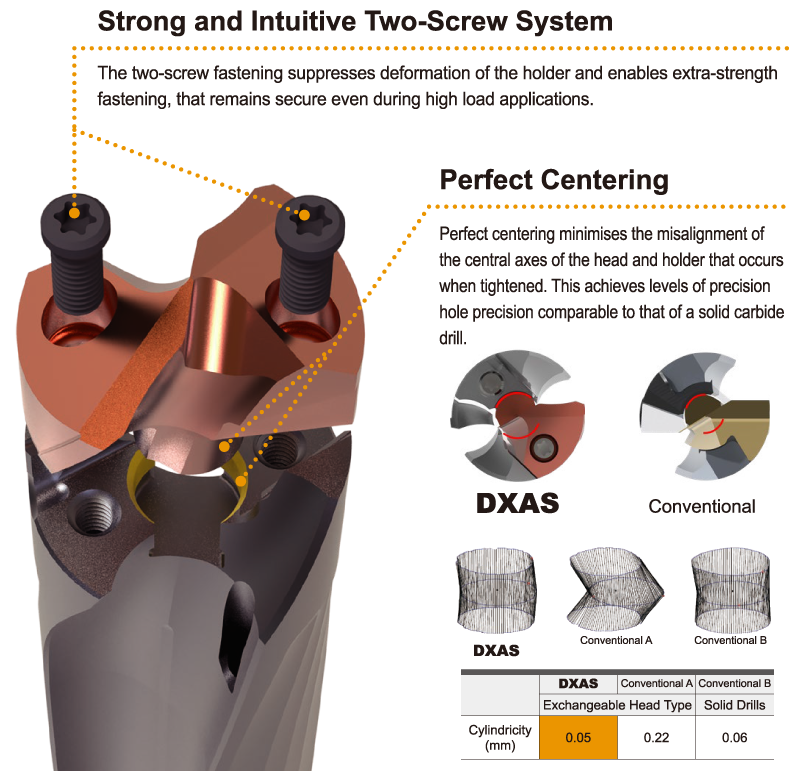

The DXAS range of exchangeable head drills from the TRISTAR drill series, is a new generation of drills that follows the DVAS solid carbide range. These drills provide customers with three main benefits of reduced running costs, together with both high precision and high efficiency

A 1.7 times improvement in machining efficiency, enabled an astonishing 8.8 times tool life. Thereby greatly increasing overall machining efficiency.