DXAS

Exchangeable Head Type Carbide Drill TRISTAR Drill Series

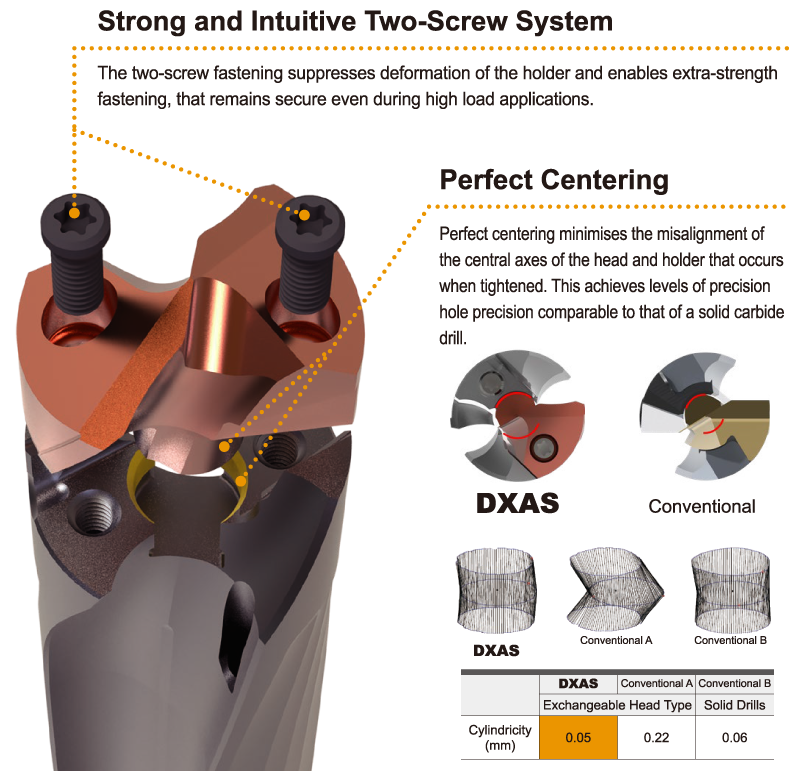

Revolutionising the head replacement system

Dramatically reduced running costs with improved accuracy and efficiency comparable to solid carbide drills.

TRISTAR Drill Series

New Drills from Mitsubishi Materials TRISTAR Drill Series

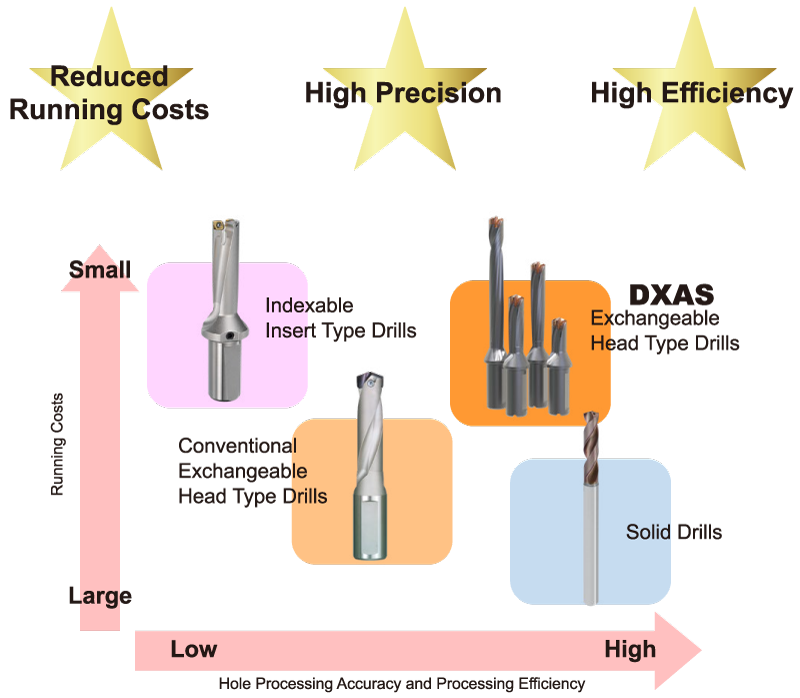

Reduced Running Costs - High Precision - High Efficiency

TRISTAR, a new generation drill series from Mitsubishi Materials provides 3 strong advantages.

Features

Exchangeable Head Type Carbide Drill DXAS

Dramatically reduced running costs with improved accuracy and efficiency comparable to solid carbide drills.

Notes from the Developer:

Simple but with excellent results

The new design was made in response to requests for longer tool life, more accuracy and efficiency. Every detail was analysed during tests and a simple fastening method was developed. It is expected that the DXAS will satisfy all criteria for optimum drilling.

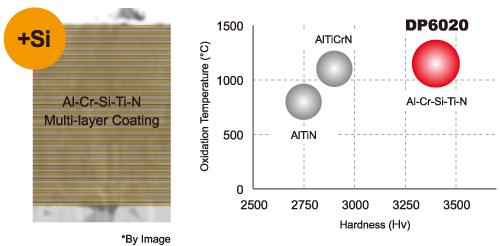

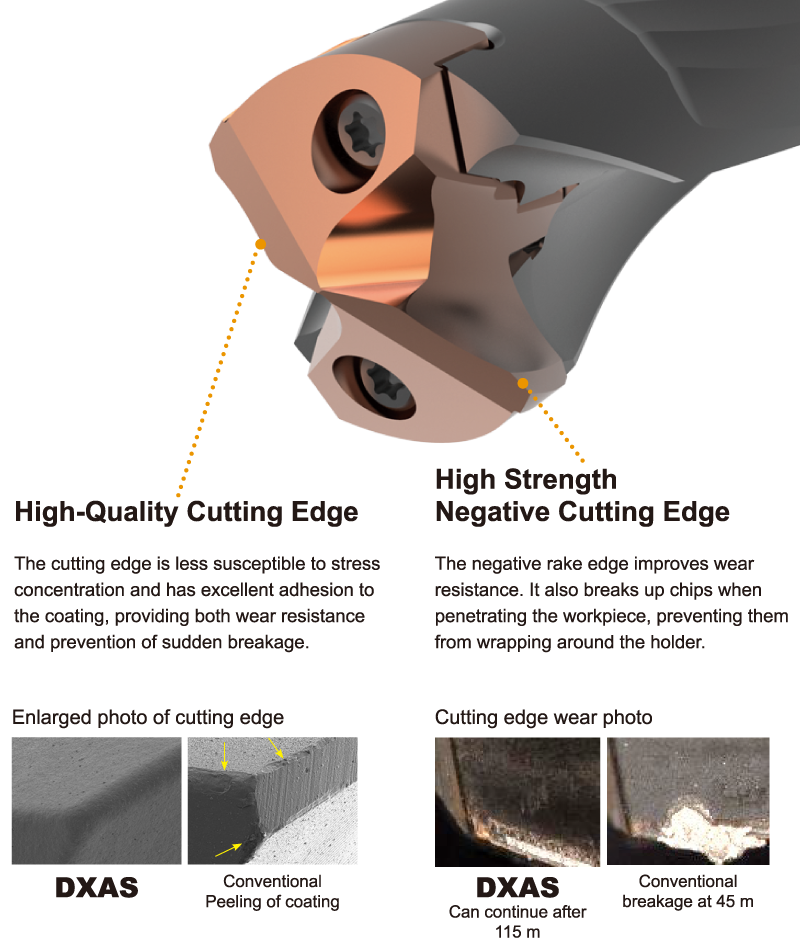

Carbide Head for P Class Materials

DP6020 with excellent heat resistance and hardness

By adding Si, the coating hardness and the temperature at which oxidation started to occur were significantly raised. This multi-layer structure also improves wear and crack resistance during cutting and provided excellent wear resistance even during high-speed, high feed machining.

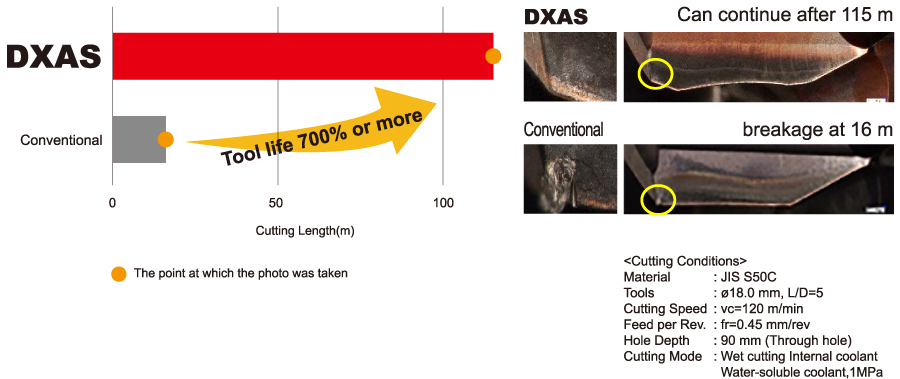

- S50C: Tool life comparison at high efficiency cutting conditions F = 955 mm/min

DXAS has excellent wear resistance even under high-efficiency conditions, achieving more than seven times the normal tool life.

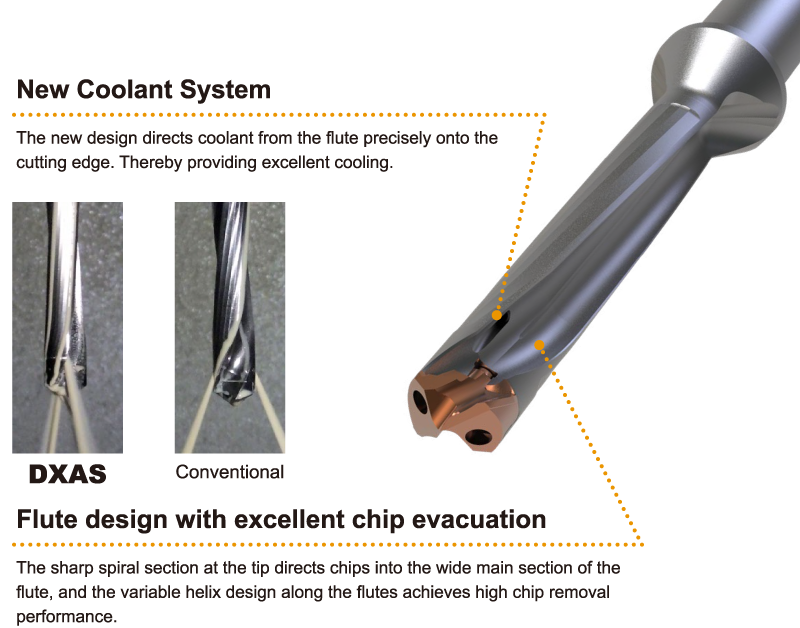

The low resistance design enables stable machining.

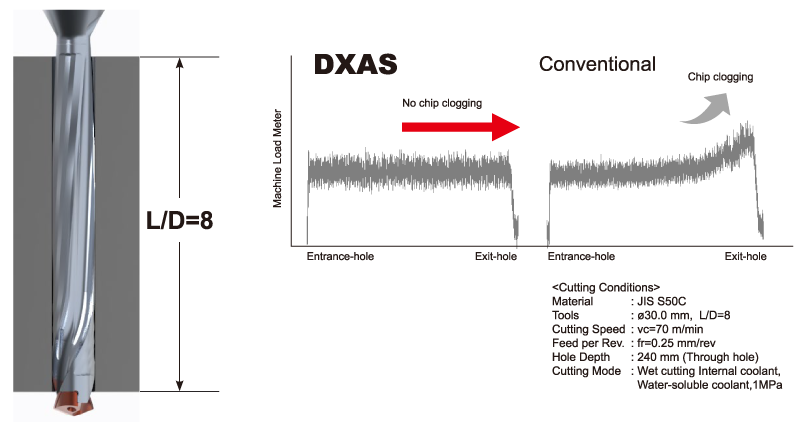

Stable Machining Even for Deep Holes

- S50C: Comparison of chip removal when drilling large diameter deep holes

Successful Examples

Successful Examples of Improved Machining Efficiency

- Successful examples of Significant Improvements in Tool Life and Machining Efficiency

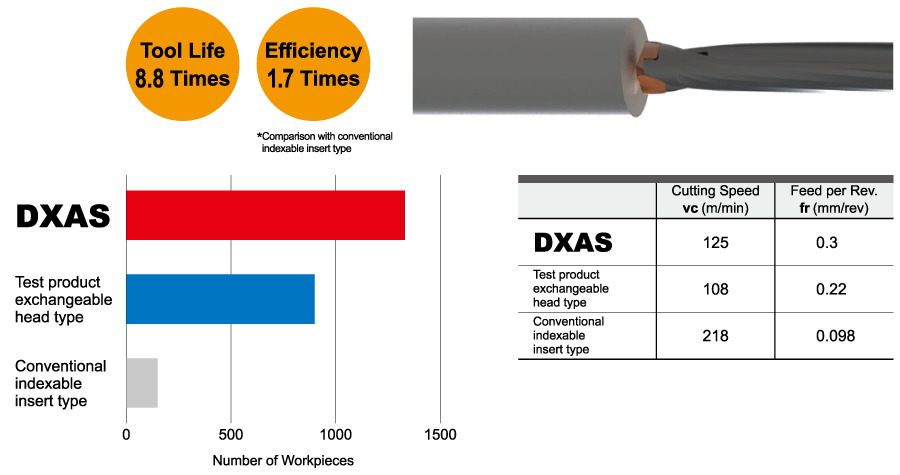

A 1.7 times improvement in machining efficiency, enabled an astonishing 8.8 times tool life.

Thereby greatly increasing overall machining efficiency.

Material : Carbon Steel / Parts : Mold Parts / Holder : DXAS2400X5F25 / Head : DXAS2450P DP6020

Hole Depth : 86.5 mm Hole dia. precision ± 0.1 mm / Cutting Mode : Wet cutting, Internal

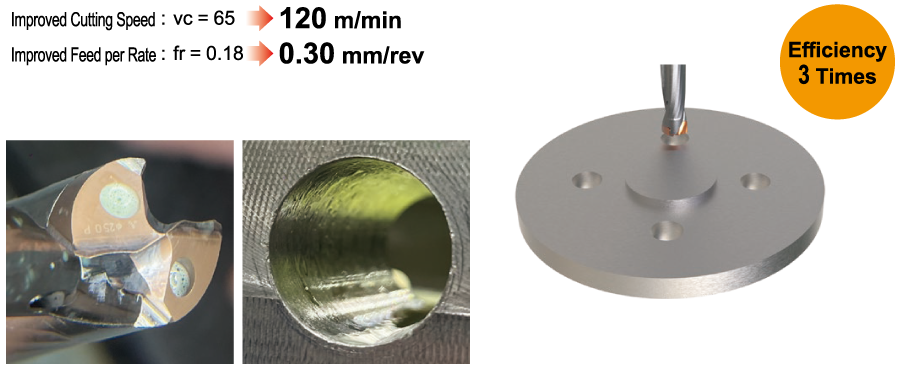

- Examples of Improved Machining Efficiency

A significant improvement of three times tool life with only slight wear.

Possibility of extending machining even further.

Material : Carbon Steel / Parts : Machine Parts / Holder : DXAS2500X5F25 / Head : DXAS2500P DP6020

Hole Depth : 85 mm / Cutting Mode : Wet cutting, Internal coolant (Water-soluble) / Machine Spindle Type : Gate-type MC

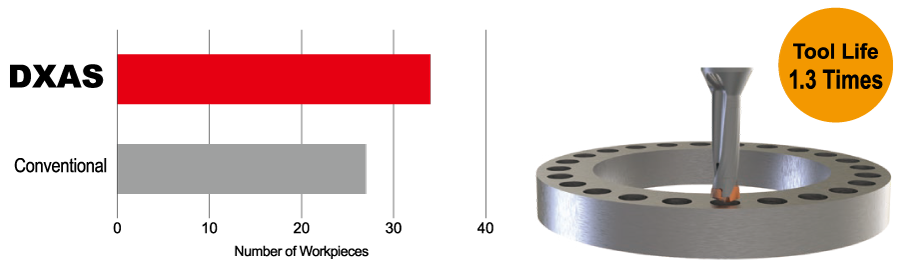

Comparison to Solid Drills

- Comparing Examples of Cutting with Solid Drills

Enables tool life that is 1.3 times greater when compared to co nventional solid drills.

Material : Alloy Steel / Parts : Flange Parts / Holder : DXAS1800X3F25 / Head : DXAS1880P DP6020

Cutting Speed : vc=110→100 (m/min) / Feed per Rate : fr=0.3 (mm/rev) / Hole Depth : 30 (mm)

Cutting Mode : Wet cutting, Internal coolan(t Water-soluble) / Machine Spindle Type : Multi-task MC

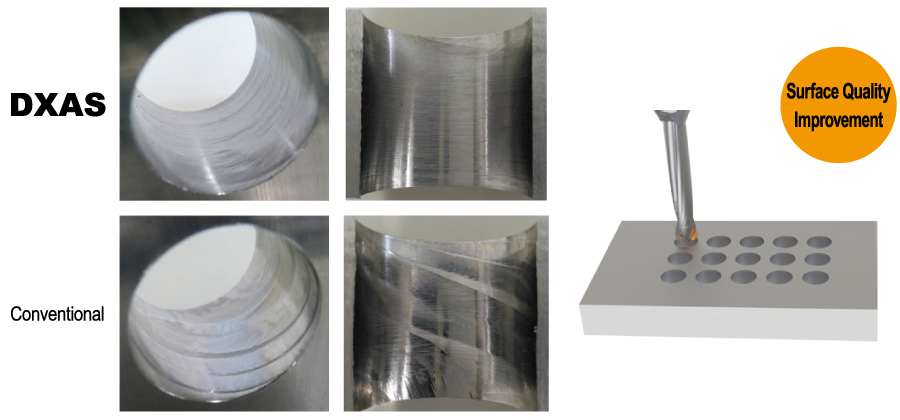

Usual problems alleviated

- Reduction of Rifling Marks

The problem of abnormal noise and rifling during alleviated.

Material : SS400 / Parts : Mold Parts / Holder : DXAS2800X5F32 / Head : DXAS2800P DP6020

Cutting Speed : vc=90 (m/min) / Feed per Rate : fr=0.29 (mm/rev) / Hole Depth : 30 (mm)

Cutting Mode : Wet cutting, Internal coolant (Water-soluble) / Machine Spindle Type : Vertical MC

Wide Range of Applications

- Example of Ductile Cast Iron Drilling

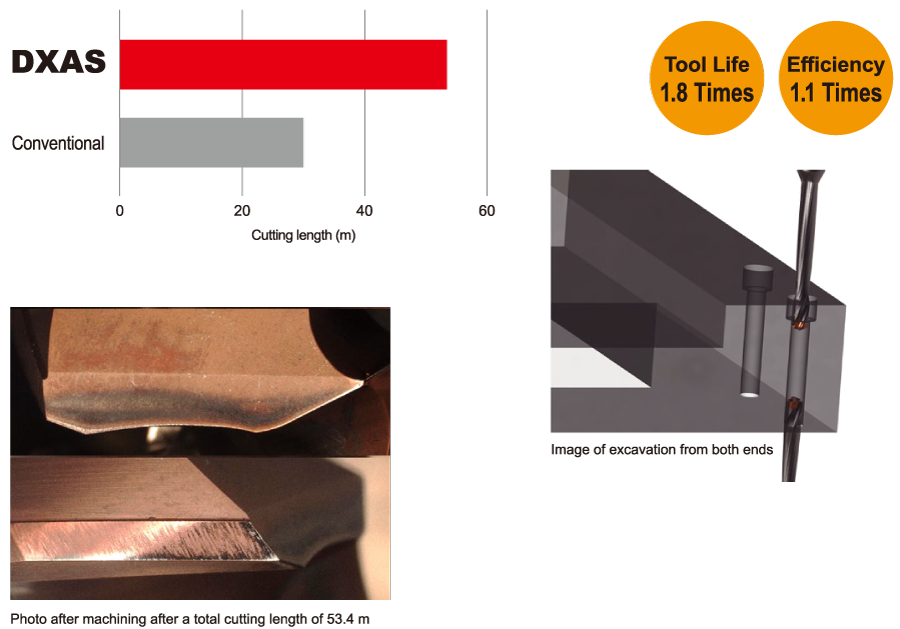

Enables 1.8 times longer tool life than conventional products without hole wandering or chip clogging.

Material : FCD400 / Parts : Plate / Holder : DXAS2200X8F25 / Head : DXAS2200P DP6020

Cutting Speed : 80 →79 (m/min) / Feed per Rate : fr=0.25 →0.28 (mm/rev)

Hole depth (one side) : 149 (mm) (Drilling from both ends), 25 mm With pilot hole

Cutting Mode : Wet cutting, Internal coolant (Water-soluble) 3MPa / Machine Spindle Type : 5-sided MC

Technical consultation from here

24/7Contact form Japan

Japan  United States

United States  Mexico

Mexico  Brazil

Brazil  EU

EU  United Kingdom

United Kingdom  Germany

Germany  Spain

Spain  France

France  Italy

Italy  Poland

Poland  Turkey

Turkey  Czechia

Czechia  China

China  Asia Pacific

Asia Pacific  Vietnam

Vietnam  Indonesia

Indonesia  India

India