Advanced Turning

Boring bars need to enter the workpiece to machine, therefore enforcing limitations on the shank diameter and tool overhang. The larger the L / D overhang ratio a boring bar has, the deeper it can machine, but as a consequence it can easily suffer from vibration (chattering). To prevent vibration, selecting the appropriate shank material and reducing the cutting resistance are important factors to consider.

In comparison with an external tool holder the overhang of a boring bar is a lot longer and as such is prone to vibrations due to cutting resistance.

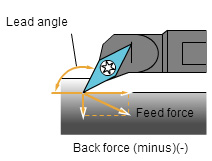

If the cutting edge of the insert is too sharp then the back force can sometimes work in the negative direction. This can lead to a reduction in the surface finish.

- Click on the buttons to learn more!

Vibrations and cutting resistance of boring bars

Preventing vibrations

The following methods are effective in preventing vibration: (order of no importance)

1. Limit the overhang

2. Increase the shank diameter (reduce the L/D). Generally for an L/D of over 5 carbide should be recommended.

3. Change the shank material (steel to heavy metal, heavy metal to carbide)

4. Use a carbide shank

5. Lowering the centre height slightly increases the rake angle and therefore can lead reduced vibrations. (Shown in the animation to the left).

6. Decrease the cutting speed.

7. Change to an insert with a smaller corner radius.

8. Change to an insert with a sharper cutting edge, or a larger rake angle.

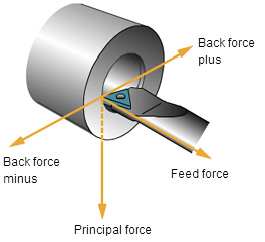

Three forces of cutting resistance when boring

Among the three forces of cutting resistance, using a high rake and selecting the optimum cutting conditions can reduce the principle and feed force. Therefore, the principle and feed forces can be easily controlled and as such have little influence, however, the back force has a far greater influence.

This is due to the fact that the back force applied on a boring bar tends to bend it. A back force value of 0 is ideal, but a minus value back force has the effect of pulling the bar in the direction of the workpiece.

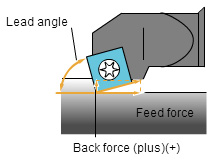

Change of back force with a different lead angle

Below you can se when the backforce becomes negative.

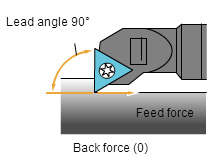

- Click on the buttons to see when the backforce also becomes zero and positive.

Back force causes inaccuracy and vibration irrespective of the size so it is necessary to consider the lead angle to help prevent these problems.

In the images to the left it can be seen if the lead angle is too large, then the back force becomes negative and therefore the machined bore will be larger than expected. Likewise, if the lead angle is less than 90° then the back force becomes positive. The best solution is to try to use an optimum lead angle of around 90° to ensure that the back force is around zero.

-

0

+

Preventing vibrations

Three forces of cutting resistance when boring

Change of back force with a different lead angle

x