Advanced Turning

Insert selection for external turning

Correct choices reduces cost

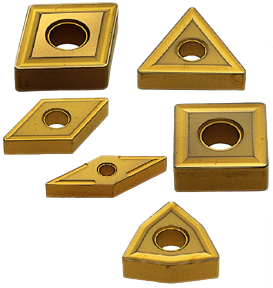

The huge combination of geometries such as triangular, square, size, thickness, corner radii and chip breakiers produces many different types of inserts. This makes insert selection as important a consideration as the choice of tool material, method, workpiece material and cutting conditions. Selecting the optimum type of insert increases working efficiency and reduces machining costs.

Insert geometry:

Effect of corner radius

Chip breakers

Click on the links to learn more!

Insert geometry

Machining methods

Cutting edge strength

Clamping strength

Economy

Effect of corner radius

Theoretical surface roughness

Cutting edge strength

Cutting resistance

Chip control

Chip breaker types

Chip breaker selection

General steel

Mild steel and difficult-to-cut material

Cast iron

Insert geometry

An insert geometry is chosen after considering all four points:

- machining method

- cutting edge strength

- clamping strength

- economy.

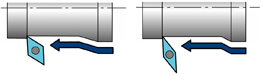

Machining methods

External turning and facing

CNC lathes are the most widely used machines and an insert geometry that enables both external turning and facing is the most common choice. 80° rhombic inserts are suitable for both roughing and finishing of faces and external diameters. Square inserts (negative) can use both sides of the insert. Therefore the number of corners is doubled, offering the user lower cost. However they can not be used for both external and facing operations.

Copying

For copying, 55° or 35° rhombic inserts are used. Although they have less cutting edge strength than 80° rhombic inserts, 55° or 35° rhombic inserts are most suitable for a wide variety of machining applications dependant on the workpiece geometry.

Besides the above, there are other insert shapes suited to threading, grooving and parting off.

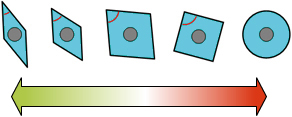

Cutting edge strength

Low

Cutting edge strength

High

A larger nose angle increases larger strength of the cutting edge, making it more effective for use in interrupted machining. However, one drawback is that with a large nose angle there are restrictions in use in areas such as deep profiling.

For stable applications such as continuous machining, triangular inserts with many corners are effective, although the cutting edge strength does deteriorate. For smaller depths of cut, 80° trigon inserts with multiple corners, maintaining high cutting edge strength, are effective.

Round inserts have the highest cutting edge strength and are the best option when requiring a superior surface finish. However, due to a large back force, round inserts are vulnerable to vibration when machining small and thin parts. Another problem with round inserts is that corner change / indexing management can be difficult.

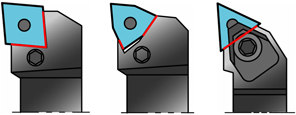

Clamping strength

Larger and thicker inserts have more of a surface area, therefore increasing the clamping strength that makes them more suitable for heavy machining.

The illustration below shows that rhombic inserts located on 2 faces in the insert pocket. Thus clamping rigidity is relatively high.

For trigon inserts the even though 2 faces are in contact with the insert pocket, the contact area is less and as such clamping rigidity is less than rhombic inserts.

For triangular inserts located in the pocket using WEDGE LOCK, only one face is in contact with the insert pocket and as such clamping rigidity is low. For triangular inserts located using LEVER LOCK, 2 faces are in contact with the chip pocket and clamping rigidity is improved. The only problem is that due to the limitation on the lead angle copy machining can not be carried out.

Economy

For negative inserts, square inserts with four cutting edges per side, eight in total are the most economical. Additionally, the cutting edge angle of 90° has high strength. After square inserts, triangular and trigon inserts with three cutting edges per side, six in total, are the next most economical.

Square inserts have eight cutting edges.

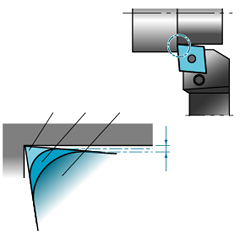

Effect of corner radius

The corner radius of an insert is also referred to as the nose radius. Larger corner radius produce smoother surface finishes and high cutting edge strength, but this also increases cutting resistance, which can easily cause vibration and poor chip control.

Note however, that inserts with different nose radius can be used on the same tool holder.

Therefore in cases where the nose radius is changed, the tool offset measurement (machining diameter correction) should be adjusted otherwise the size of the components being machined will differ.

R0.0 R0.4 R0.8

Offset amount

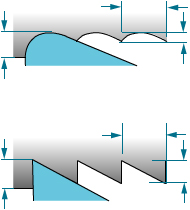

Theoretical surface roughness

When the corner radius is Re(mm), and the feed is f (mm / rev), the theoretical surface roughness h(μm) can be found with the formula below.

With a fixed feed rate, a larger corner radius theoretically produces a superior surface roughness.(Figure 1). However, when using the same corner radius but with a variation in the depth of cut, as shown in Figure 2 it can be seen that the average chip thickness decreases when the depth of cut is reduced. This will result in a reduction in the cutting heat generated when machining, which will then result in a built up edge that can cause the surface finish to deteriorate.

h=f² / 8Re1,000

Feed

Depth of cut

Depth of cut

Theoretical

surface

roughness

Theoretical

surface

roughness

Feed

Figure 1 showing the relationship between corner radius and surface finish roughness.

Feed

Depth of cut

Chip

Depth of cut

Feed

Cutting edge

Cutting edge

Chip

Figure 2 showing the relationship between depth of cut and chip thickness.

Figure 1

Figure 2

Cutting edge strength

Corner radius

In general, approximately 0.4mm 1.2mm corner radius are used for turning. For heavy machining, larger corner radii are used as they have higher cutting edge strength. Whereas for finishing, smaller corner radius are generally used.

Cutting resistance

Corner radius

A corner radius that is too large increases cutting resistance (back force) in the direction of the workpiece and causes machining inaccuracies such as poor cylindricity* and vibration.

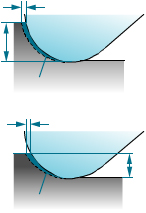

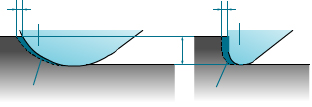

Chip control

Feed

Feed

Depth of cut

Chip

Cutting edge

Cutting edge

Chip

Using a large corner radius at a small depth of cut has the same effect as increasing the lead angle. This reduces the chip thickness and the chips tend elongate and flow away from the work surface.

The illustration show the relationship between corner radius and chip thickness.

Chip breaker types

Ground type

The ground type has a breaker that is ground into the rake face. It usually has a sharp edge and can be used to make right or left handed inserts.

Clamp-on type breaker

A special single chip breaker or height adjustable chip breaker piece is clamped on top of the insert and used for different cutting conditions. It is used often on flat top ceramic inserts.

Moulded type

The chip breaker form is moulded into the insert itself. Owing to this flexibility of chip breaker design, the chip control range is widened and this type of breaker can be used without being handed. This makes the moulded type breaker suitable for complex tooling and is the most widely used.

The parameters for choosing chip breakers are workpiece material and cutting conditions. Workpiece materials are classified for chip control purposes into general steel, mild steel difficult-to-cut materials such as stainless steel and more fragile materials such as cast iron.

Ground type

Clamp-on type breaker

Moulded type

There are three types of chip breakers.

Click for more information

Chip breaker selection

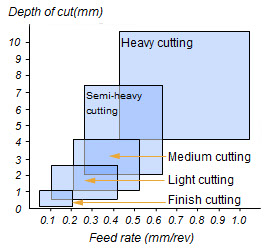

It is impossible for one particular chip breaker to provide effective chip control disposal properties for all cutting conditions. As shown in the graph below, the design of chip breakers will vary according to the depth of cut and the feed rate. For each particular machining operation whether it be heavy, semi-heavy, medium, light, or finish machining a dedicated chip breaker geometry is necessary. Therefore it is essential to select the correct chip breaker for the application that is to be carried out.

General steel

For general steel, a chip breaker is chosen according to the cutting conditions. Depth of cut and feed are especially important and the breaker should be chosen according to the machining area classified by these two cutting conditions. In addition, consideration should also be given as to whether the application is finishing, light machining, medium machining, semi-heavy or heavy machining. Each tool manufacturer tends to group their chip breakers into these cutting areas.

Mild steel and difficult-to-cut material

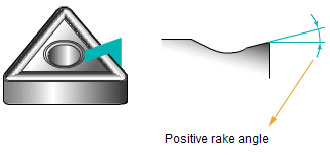

For mild steel and difficult-to-cut materials, chip control, welding resistance and long tool life are required from chip breakers. Therefore, it is necessary to comprehensively assess all these parameters together. In general, to prevent cutting temperatures from rising, a chip breaker with a large positive rake angle and sharp edge is used. However, for workpiece materials vulnerable to work hardening such as stainless steel, cutting edge strength is also an important point as the cutting edge can easily be damaged.

Cast iron

For cast iron, chips do not have to be aggressively curled and broken due to the crack type chips that are usually produced. A chip breaker that can maintain both cutting edge strength and reduce cutting resistance is the most suitable.

x