Advanced Turning

Selecting a boring bar

Choosing the lead angle

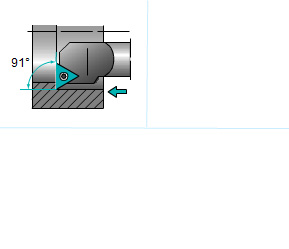

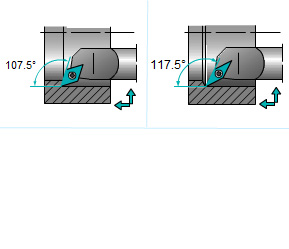

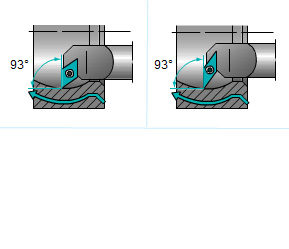

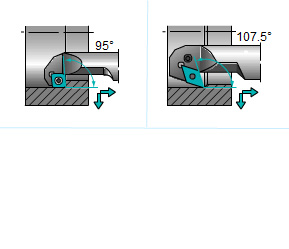

Boring requires, like external turning, that the appropriate lead angle is determined by the application. When machining a through hole, an economical square insert with four cutting edges per insert can be used with a lead angle up to 90°. However, when facing to centre, boring bars with a large lead angle should be chosen to reduce cutting resistance.

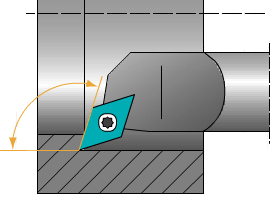

Back boring, (cutting away from the workpiece) is a special machining method used only for boring. Back boring can be used when concentricity* of the outer and inner diameters is important, external turning and boring should be completed in a single set up. In this case, boring close to the chuck can be problematical, but with back boring type bars, machining without unclamping the workpiece is possible.

Click the links below to read more about different turning tools.

Image showing the lead angle when boring.

Lead angle

Criteria for selecting a shank diameter

When choosing a boring bar, a certain shank diameter has to be chosen. Boring bar overhangs tend to be long, so to maintain rigidity it is advantageous that the shank diameter be as large as possible.

The key to choosing the appropriate shank diameter is to compare the minimum machining diameter of the boring bar, the required bore diameter, and to choose a shank diameter as large as possible. However, if the shank diameter is too close to the bore diameter, chip control can be a problem. This therefore means that the shank diameter should be chosen according to the application.

Negative insert and wall interference

Click on the captions to learn more about each boring bar!

If outer facing and boring is required the use of a 80 deg rhombic insert is recommended.

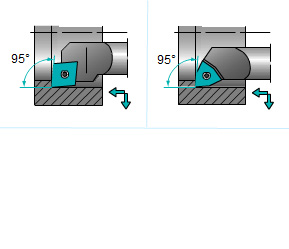

For boring where there is a need internal facing a boring bar with a large lead angle should be selected.

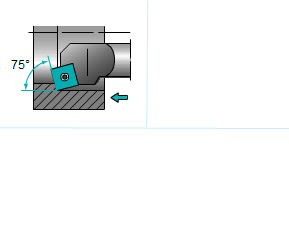

For plain copy machining a large lead angle is recommended.

Back boring is an option that is chosen if the workpiece geometry makes it necessary, if there are special tolerance requirements or if the tool path requires it.

Linear machining

Through hole

Linear machining & Facing

Linear machining & Infeed facing

Copying

Back boring & Black feed facing

Boring bars

Negative insert and wall interference

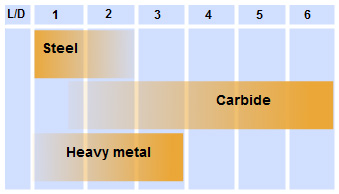

The materials that can be used for shanks of boring bars include steel, heavy metal and cemented carbide. For a boring bar with a steel shank, if the L/D is greater than 4-5, then it is prone to vibrations and as such limits the depth of cut and feed rate.

When vibrations occur, this not only results in poor surface finish it also causes micro-chipping of the cutting edge and as such the tool life can decrease.

Heavy metal boring bars and cemented carbide boring bars are used to increase the rigidity of the boring bar and as such prevent vibrations thus enabling them to machine to larger L/D ratios when compared to steel shank boring bars.

Criteria for selecting a shank diameter

View various types of boring bars

Boring bar material

x