Advanced Turning

Chip control

Need for chip control

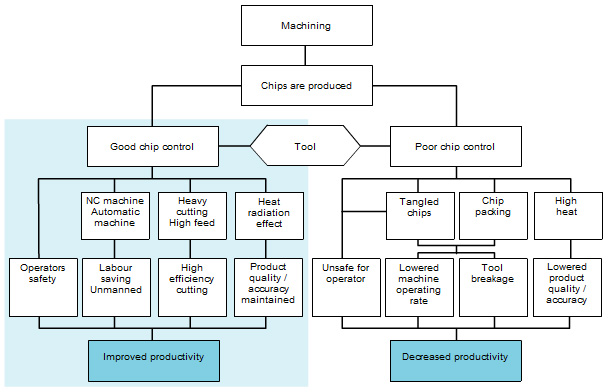

During machining chips are produced. The chips themselves produce valuable research and diagnostic data for metal cutting engineers, while for production engineers, chips tend to be troublesome and hinder productivity.

Machine tools are constantly improving, highly capable robots have been developed and recently, automation of production systems such as FA (factory automation) has greatly increased. To achieve automation of production systems, machining process problems must be eliminated. To achieve this, effective chip control and highly reliable tooling has to be implemented.

If continuous or scattered chips are produced resulting from poor chip control, or vibration occurs, tool damage and deterioration of the product will result. Additionally, vibration leads to a decrease in the accuracy of the component. As stated above, the quality of chip control greatly affects the whole production process, including safety, efficiency, accuracy and product quality control.

Click the links below to view the effects of chip control on productivity.

Typical chip breakers

Ground chip breaker

Moulded chip breaker

- High sharpness.

- Good surface finish.

- Mainstream recent development.

- Inexpensive.

- Wide chip control range.

Controlling chips with breakers is the easiest and the most effective method, so manufacturers are constantly engaged in research and development for different chip breaker geometries that will be effective in ever widening application areas.

Effects of chip control on productivity

View map: Effects of chip control on productivity

x