Advanced Turning

Basics of designing chip breakers

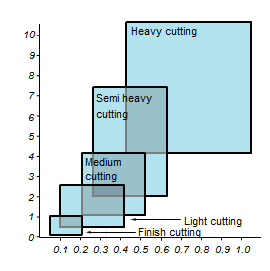

For rough machining such as heavy and semi-heavy machining with a large depth of cut and at high feed rates, chip control and the tool’s fracture resistance needs to be considered. This means that chip breakers have to be designed to have a large breaker width where the chip pocket is widened and so improves chip control. When prioritizing cutting edge strength, a flat, negative land is usually designed for the cutting edge.

Meanwhile, for finishing, due to the low feed and small depth of cut, it is necessary to decrease the chip curl radius so that they are easily broken. These types of chip breakers are designed to have a smaller breaker width. The load on the cutting edge during finishing is low and sharpness is prioritized rather than cutting edge strength, therefore allowing a design with a small edge honing and a positive land.

Definition of cutting

Feed rate (mm/rev)

Depth of cut (mm)

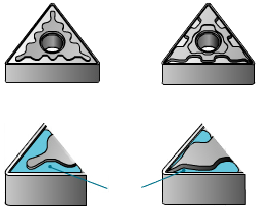

Chip pocket differences according to use

Breaker for semi-heavy

machining

Breaker for finishing

Chip pocket

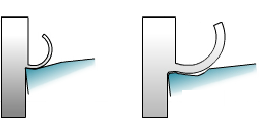

Wall positioning differences according to use

Insert

Insert

Breaker for finishing

Breaker for heavy machining