Advanced Turning

Functions of chip breakers

The function of a chip breaker is to improve chip control and to reduce cutting resistance. A better balance between the two will increase the machining performance.

If chips can be broken into suitable lengths by the chip breaker, they will not wrap around the workpiece, vibration will decrease and tools will not be so easily damaged. Chip breakers also affect cutting resistance. Reduced cutting resistance can avoid chipping and fracturing of the cutting edge caused by vibration. Additionally, lower cutting resistance can decrease the load and heat, and can delay the development of tool wear.

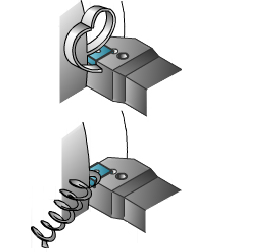

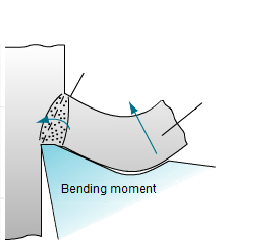

How are chips actually broken? Grooved type chip breakers near the cutting edge make the chips curl and discharge quickly. In this case, the chips are curled and discharged when broken as they hit the workpiece or cutting edge flank, in other words, when the flow of material is hindered. Chips with a large radius curvature are broken when a bending moment* opposite to the direction of the curl occurs. Additionally, chips can curl in on themselves and are broken by their own weight. As seen in the bottom picture to the right, chips can be broken by a bending moment when the curvature radius of the chip formed by the chip breaker is too small.

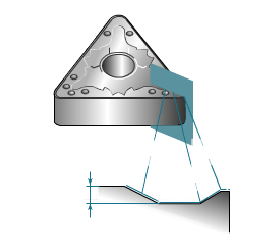

Insert nomenclature

Chip breaker depth

Wall

Land

Plastic condition

Force put on the chip breaker

Chip breaker function

Factors for breaking chips