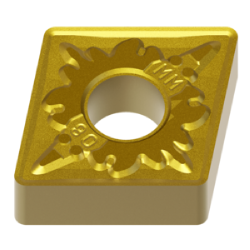

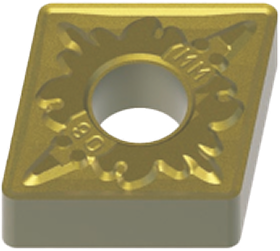

MC7125

ステンレス鋼加工のオールラウンダー

ステンレス鋼旋削加工の第一推奨材種

連続切削から断続切削まで、幅広い加工形態をカバー

さまざまなステンレス鋼、部品に対応

The standard Nano Texture Technology has been improved and developed to be an industry leading standard for crystal growth of Al2O3 coatings. This Super Nano Texture Technology increases tool life and wear resistance due to the fine, dense crystal growth process.

The extra strength of the adhesion between the coating layers suppresses peeling during machining of stainless steels.

Excellent welding resistance

The sharp design of the corner radius and main cutting edge improves welding resistance and prevents problems.

※MC/MP7100 series negative inserts new design

The tool life has doubled compared to previous inserts.

Tool life was improved even on workpieces with severe interrupted cutting.

Tool life has been increased by 1.4 times for large workpieces.

Achieved a 35% increase in the number of machining operations without fracturing.

Technical consultation from here

24/7Contact form Japan

Japan  Japan

Japan  United States

United States  Mexico

Mexico  Brazil

Brazil  EU

EU  United Kingdom

United Kingdom  Germany

Germany  Spain

Spain  France

France  Italy

Italy  Poland

Poland  Turkey

Turkey  Czechia

Czechia  China

China  Asia Pacific

Asia Pacific  Thailand

Thailand  Vietnam

Vietnam  Indonesia

Indonesia  India

India ![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

![]() For finish cutting

For finish cutting

![]() For medium cutting

For medium cutting

![]() For rough cutting

For rough cutting

フェライト系SUS430

オーステナイト系SUS304,

SUS316

マルテンサイト系SUS420J2

析出硬化系SUS630

二相系ステンレス鋼SUS329J1

ステンレス鋼加工のオールラウンダー

ステンレス鋼旋削加工の第一推奨材種

連続切削から断続切削まで、幅広い加工形態をカバー

さまざまなステンレス鋼、部品に対応

第一推奨新設計

新設計により、ステンレス加工における切れ味と耐溶着性が向上しました。

刃先安定性UP

刃先安定性と切りくず処理性に優れた汎用ブレーカです。

切れ味UP

シャープな切れ味で、絡みのない切りくずを生成します。

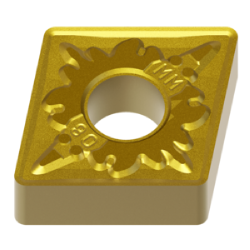

さらに…高速切削で生産性をあげたい

高速切削加工を極めるスピードスター

オーステナイト系ステンレス鋼の中型から大型部品に対し、

切削速度250 m/min以上の高速切削条件による加工時間の短縮を実現

第一推奨新設計

新設計により、ステンレス加工における切れ味と耐溶着性が向上しました。

軽切削用

軽切削領域に適した強すくい角により、バリの抑制に適しています。

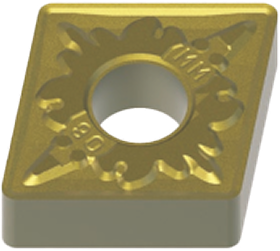

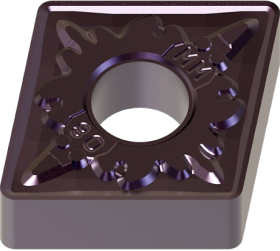

さらに…黒皮、強断続切削をしたい

衝撃に負けない不屈のファイター

スリット、キー溝、穴付き被削材の断続加工や

鍛造材・鋳造材の荒加工に最適

第一推奨

PVDコーティングとの組み合わせで、荒加工でも切れ味に優れます。

荒加工用

強断続加工に優れた刃先強度の高い形状です。

刃先安定性UP新設計

シャープな切れ味で、絡みのない切りくずを生成します。

衝撃に負けない不屈のファイター

スリット、キー溝、穴付き被削材の断続加工や

鍛造材・鋳造材の荒加工に最適

第一推奨

PVDコーティングとの組み合わせで、荒加工でも切れ味に優れます。

荒加工用

強断続加工に優れた刃先強度の高い形状です。

刃先安定性UP新設計

シャープな切れ味で、絡みのない切りくずを生成します。

さらに…安定した連続切削をしたい

ステンレス鋼加工のオールラウンダー

ステンレス鋼旋削加工の第一推奨材種

連続切削から断続切削まで、幅広い加工形態をカバー

さまざまなステンレス鋼、部品に対応

第一推奨新設計

新設計により、ステンレス加工における切れ味と耐溶着性が向上しました。

刃先安定性UP

刃先安定性と切りくず処理性に優れた汎用ブレーカです

切れ味UP

シャープな切れ味で、絡みのない切りくずを生成します。