External Grooving for Small Parts Machining

GT Holder

Covering a wide range of shallow grooving operations.

Added 0° offset and 90° holders

Features

External Grooving for Small Parts Machining

GT Holder

Newly added 90° holder

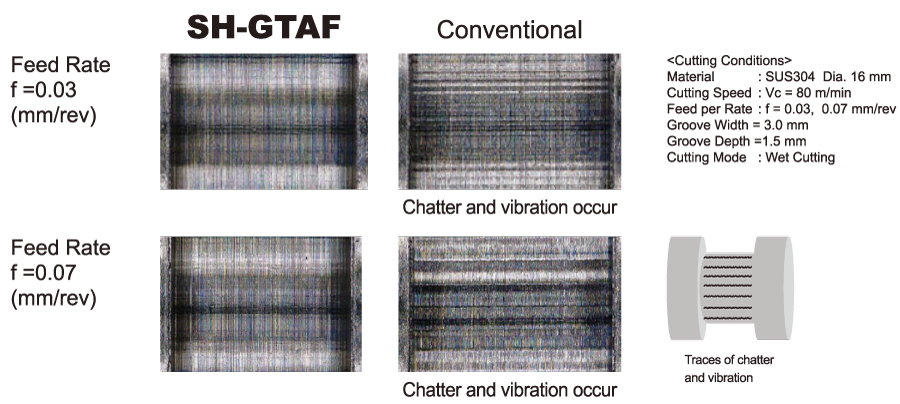

The neck dimensions have been optimised to improve resistance to chatter and vibration.

- SUS304: Comparison of machined surfaces (round shank holder)

High rigidity and large machining depth provide excellent resistance to chatter and vibration.

External Grooving for Small Parts Machining

GTAH, GTBH, GTCH

Back Clamping Mechanism

Even gang type tool posts on Swiss automatic lathes, tools can be changed quickly and accurately using the same wrench on both sides, improving machine operating efficiency.

*Offset type is not included.

PVD Coated Grades for High Precision and Small Parts Machining

MS7025

Dramatically improved welding and wear resistance in low feed machining with a more precise nano-multilayer coating

Features

Nano-Multilayer Coating

By combining the high lubrication layer with excellent welding resistance, and the high hardness layer with a greater wear resistance that suppresses the progress of wear at the nano-level, the film damage is significantly reduced and the welding and wear resistance are dramatically improved.

Effects of the High Lubrication Layer

The nano-level, high lubrication layer suppresses built-up edge caused by chip welding which tends to occur in low feed machining and in addition reduces machining marks on the component surface.

Cutting Performance

Comparison of Surface Roughness and Cutting Edge Damage : Pure iron-based soft magnetic materials

The surface roughness is excellent because damage caused by welding is suppressed. It also has excellent wear resistance.

Surface Roughness with Finishing Groove Bottom Diameter 11mm

Cutting Edge Damage

Carbide Grade (Non Coated)

MT2015

It has the usual wear resistance of carbide but is also tough and therefore resists sudden fractures. It can be expected to extend the life of non-ferrous metals such as aluminium alloys.

Cutting Performance

Comparison of Cutting Edge Damage : A6061

By suppressing damage to the cutting edge caused by welding, longer tool life can be expected.

PVD Coated Grades

VP15TF/VP15KZ

(Al,Ti)N coated grade with excellent heat resistance and adhesion strength.

It is highly versatile and can be used in a variety of machining processes.

Cutting performance Video

Technical consultation from here

24/7Contact form

Japan

Japan  United States

United States  Mexico

Mexico  Brazil

Brazil  EU

EU  United Kingdom

United Kingdom  Germany

Germany  Spain

Spain  France

France  Italy

Italy  Poland

Poland  Turkey

Turkey  Czechia

Czechia  China

China  Asia Pacific

Asia Pacific  Vietnam

Vietnam  Indonesia

Indonesia  India

India