MX3030

Cermet Grade for Milling

Expands The Effective Application Range of Cermet Grades

Enables excellent surface finishes even at highly efficient machining conditions.

Improved machining efficiency by maintaining excellent surface finishes even at large depths of cut.

Cermet has a low affinity with iron, excellent thermal stability and oxidation resistance, and is a suitable grade for finishing.

However, it does not have the same bonding strength as cemented carbide, and the challenge is to compensate for fracture resistance.

MX3030 has higher thermal conductivity than conventional products and has excellent thermal cracking resistance. Therefore It is possible to suppress wear and maintain the surface finish.

Also, since it has excellent toughness, it can be expected to improve machining efficiency through machining at large depths of cut.

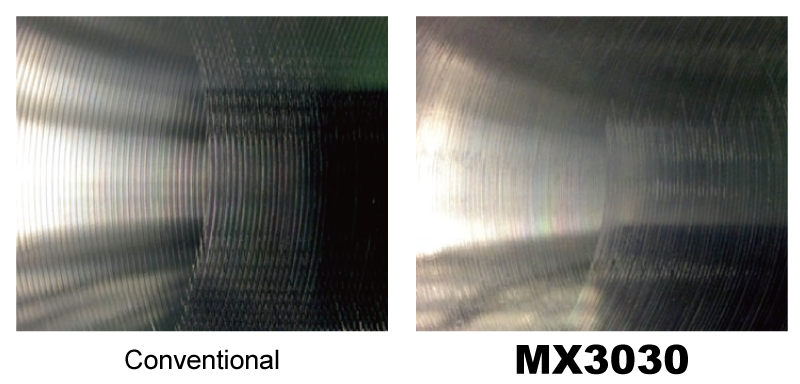

Mild Steel SS400, Finished Surface Comparison

Workpiece Material : JIS SS400 Cutter Dia. : DC=125mm Cutting Speed : 200m/min Feed per Tooth : 0.1mm/t.

Depth of Cut : ap=2.0mm Width of Cut : ae=100mm

Cutting Mode : Dry Cutting 8 Inserts Centre Cut After 8m Cutting Work

Cutting Performance

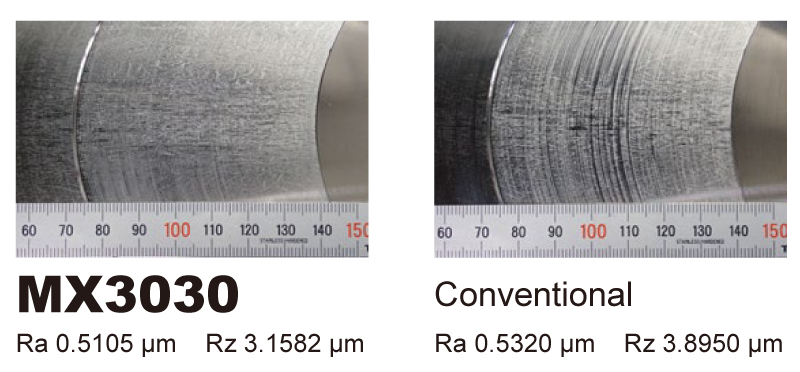

Finished surface comparison when machining SCM440 Alloy Steel

The MX3030 grads produced an excellent finished surface with uniform machining marks and only a slight cloudiness.

Workpiece Material : JIS SCM440 Tool : ASX400-JL Cutting Speed : vc=250 m/min Feed per Tooth : fz=0.05mm/t. Depth of Cut : ap=0.5mm Width of Cut ae=100mm Cutting Mode : Dry Cutting

Finished surface comparison when machining SCM440 Alloy Steel

The MX3030 grades produces a refined and smooth surface finish.

Workpiece Material : JIS SCM440 Tool : APX3000R324SA32SA Cutting Speed : vc=120 m/min

Feed per Tooth : fz=0.08mm/t. Cutting Mode : Dry Cutting Single Insert

Expanding the grade for use on other types of milling cutters

In addition to the insert for WSX445, inserts with MX3030 have been added to other cutters.

Inserts with MX3030 are standardized to the following cutters.

APX3000 / WSX445 / ASX445 / ASX400 / OCTACUT / BRP / CESP,SFSP,CGSP / BAP300 / BAP400 / SRM2

Technical consultation from here

24/7Contact form Japan

Japan  United States

United States  Mexico

Mexico  Brazil

Brazil  EU

EU  United Kingdom

United Kingdom  Germany

Germany  Spain

Spain  France

France  Italy

Italy  Poland

Poland  Turkey

Turkey  Czechia

Czechia  China

China  Asia Pacific

Asia Pacific  Vietnam

Vietnam  Indonesia

Indonesia  India

India