![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

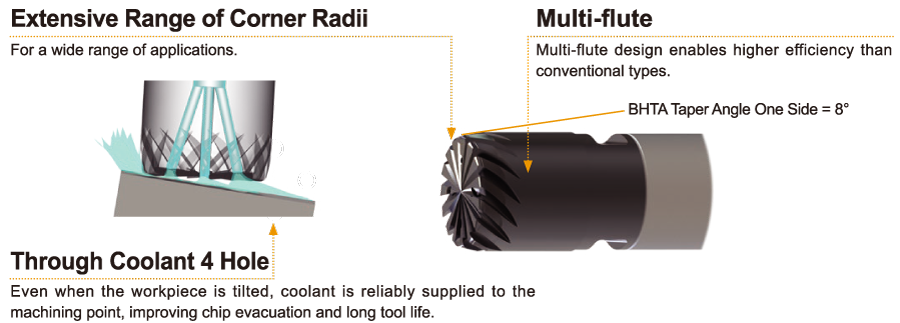

MITSUBISHI MATERIALS CORPORATION, Metalworking Solutions Company (Company President: Kazuo Ohara, Address: Marunouchi, Chiyoda-ku Tokyo) announced today that the iMX series of interchangeable head end mills will be expanded with the addition of the new iMX-C8 T/C10T/C12T/C15T-E taper flute, corner radius types, featuring a through centre coolant hole and compatible ER Collets. Sales will begin on October 1st.

The iMX series has received a favourable reception in the market as a revolutionary end mill system that provides excellent economy and enables efficiency, high accuracy and rigidity by combining the advantages of both solid carbide and indexable end mills. Overall rigidity close to that of solid type end mills is realised because the clamping faces of the holder and head are both manufactured from carbide.

To improve chip discharge, Mitsubishi Materials has launched the centre through coolant hole type with tapered flute, corner radius geometry as well as compatible ER Collets that can be used with automatic turning machines and multi-turret machines.