![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

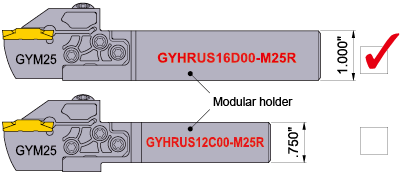

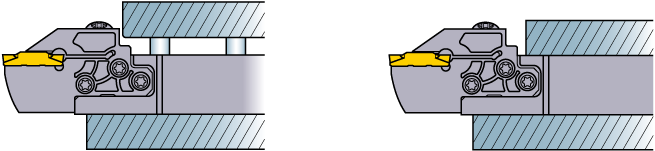

To ensure sufficient clamping rigidity, select a modular holder with the largest possible shank size.

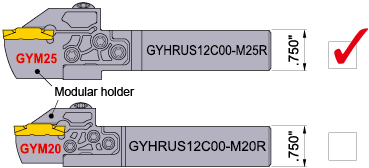

If there is no restriction for use, select the largest modular blade for the same shank size.

Select the shortest possible blade suitable for the application.

Select the shortest possible blade suitable for the application.

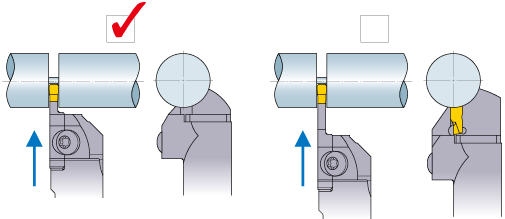

<Grooving/Cross-feed machining>

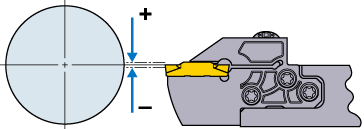

Set the cutting edge height to ±.004" parallel to the central axis.

<Cutting off>

Set the cutting edge height to 0 – +.008" parallel to the central axis.

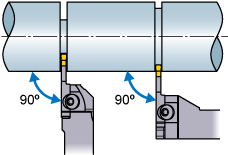

Set the insert perpendicular to the central axis.

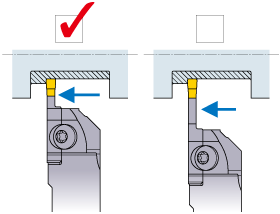

When setting the tool, ensure that the overhang is as short as possible and avoid the step difference part as above figure shows.

Japan

Japan  Japan

Japan  United States

United States  Mexico

Mexico  Brazil

Brazil  EU

EU  United Kingdom

United Kingdom  Germany

Germany  Spain

Spain  France

France  Italy

Italy  Poland

Poland  Turkey

Turkey  Czechia

Czechia  China

China  Asia Pacific

Asia Pacific  Thailand

Thailand  Vietnam

Vietnam  Indonesia

Indonesia  India

India ![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

![]() For finish cutting

For finish cutting

![]() For medium cutting

For medium cutting

![]() For rough cutting

For rough cutting