![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

Improving Surface Finish

Under the same machining conditions as conventional breakers, but with the feed rate increased, the surface finish of the work materialcan be improved.

Improving Efficiency

High feed rates not only shorten machining times but also make itpossible to combine roughing and finishing operations.

Increased Tool Life

When a change to high feed conditions, the time required to cut one component is decreased, thus more parts can be machined with each insert. In addition, the high feed rate prevents rubbing, therefore,delaying the progression of wear and increasing the tool life of the insert.

Improving Chip Control

Under high feed conditions, the chips generated become thicker and are more easily broken, thus, chip control is improved.

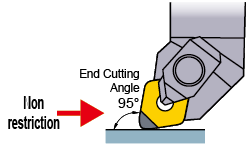

Preventing the cutting edge from vibration during boring and turning of small diameter work material as well as providing excellent surface finish.

Standard holders can be used.

(*A double clamp, high rigidity tool is recommended.)

Use a holder with end cutting angle 93° for improving wiper efficiency. A holder with end cutting angle 91° can improve wiper efficiency, however, there is no wiper efficiency with other end cutting angles (60°, 90°,107°etc.).

Japan

Japan  Japan

Japan  United States

United States  Mexico

Mexico  Brazil

Brazil  EU

EU  United Kingdom

United Kingdom  Germany

Germany  Spain

Spain  France

France  Italy

Italy  Poland

Poland  Turkey

Turkey  Czechia

Czechia  China

China  Asia Pacific

Asia Pacific  Thailand

Thailand  Vietnam

Vietnam  Indonesia

Indonesia  India

India ![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

![]() For finish cutting

For finish cutting

![]() For medium cutting

For medium cutting

![]() For rough cutting

For rough cutting