![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

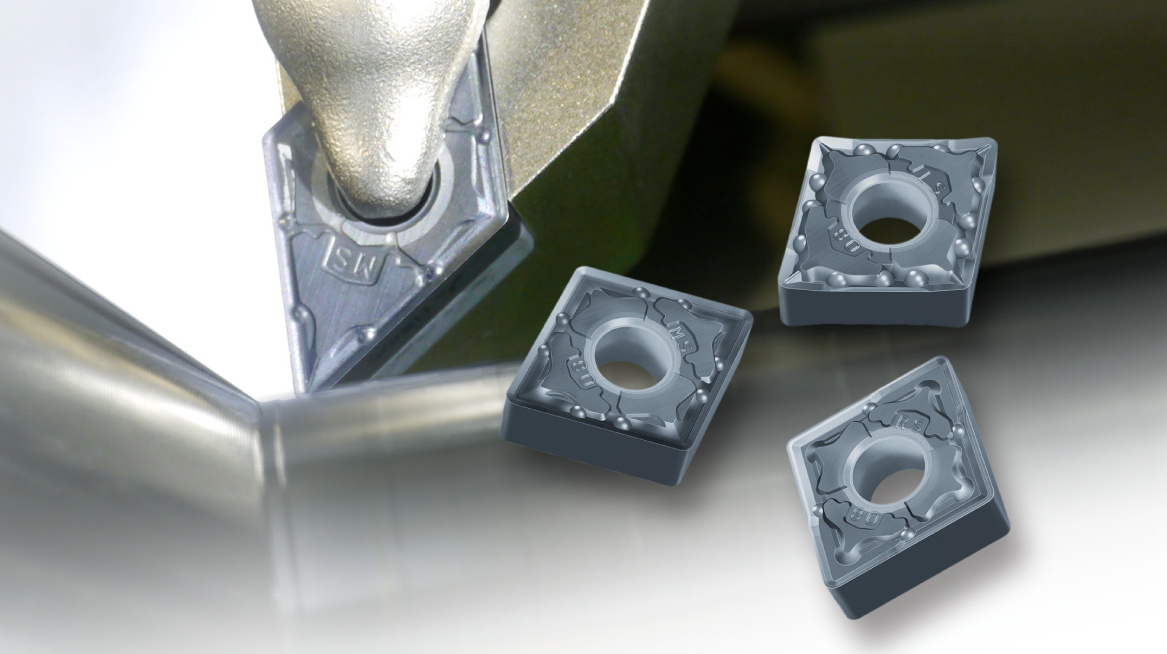

The MP9000/MT9000 series is ideal for turning difficult-to-cut materials such as titanium, heat resistant and corrosion resistant alloys that are typically used in the aircraft and medical industries. The new chip breakers within the range help prevent problems such as continuous chip wrapping and chipping of the cutting edge. The MP9000/MT9000 series has a good reputation from customers by providing superior wear, fracture and welding resistance and for also enabling longer tool life.

To expand the application options available, new chipbreakers have been added, plus a range of inserts with an alternative MJ type are also now available.

1. LS breaker for light cutting: Enhances chip disposal for depths of cut smaller than the corner R.

2. MS breaker for medium cutting: Smooth chip generation and prevents chip tangling due to the large 2-step rake angle.

3. RS breaker for rough cutting: Controls chip welding and abrasion at the depth of cutline during low speed cutting due to the positive land geometry.

4. MA breaker for general purpose use: Provides excellent cutting edge sharpness due to the positive land geometry.

5. MJ breaker: Alternative chipbreaker for the LS breaker (for light cutting) and MS breaker (for medium cutting). It prevents damage at the depth of cut line that can occur easily when turning difficult-to-cut materials.

| Product name | LS breaker, MS breaker, RS breaker, MA breaker, MJ breaker |

|---|