Tool grades

PVD Coating

Under the PVD method, a coating is applied to the surface of a metal under low temperatures. This method is used quite frequently with drills, end mills, and threading tools. This method can also be used for steel (other than cemented carbide) and cermet materials.

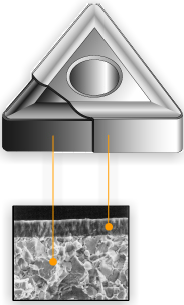

One example of this is a two-layer structure of titanium aluminum nitride deposited on a base metal.

The process is complicated and time-consuming for any coating. You can use this fact as a simple explanation as to the high cost of tools coated using this method. Because a cathode is required for each coating they are conducted in single layers.

As the coating temperature of PVD is lower (up to 700C, 1290F) than that of CVD damage to a substrate during coating (a decrease in toughness) is reduced. So, even the sharp edge* can maintain toughness. PVD is applied to many tools, including drills, end mills and threading tools.

In the past, almost all PVD coating materials have been either TiN or TiCN. However with the rapid development of PVD coating technology, (Al,Ti)N coating has become the most popular coating material in recent years.

A dedicated substrate is not required. PVD coating can be performed on existing.

- Click below for more information!

Substrates coated using PVD

The temperatures used for PVD coating are lower than that of CVD coating. Therefore, during PVD coating the substrate is not damaged and the toughness of the substrate is not affected. As a result, PVD coating can be applied to a wide range of substrates, such as cemented carbides and cermets as well as high-speed steel tools and carbide brazed tools, both of which have lowered hardness and strength at high temperatures

PVD coating is also often used for drills, end mills and threading tools, etc., because it can maintain the cutting edge strength of tools that require a sharp cutting edge.

Process

This is a process that is carried out at relatively low temperatures. The coating is conducted physically in the form of either vacuum evaporation, sputtering or ion plating. The result of this process is that a thin film of hardened particles is left on the surface of the carbide substrate.

Advantages and disadvantages with PVD method

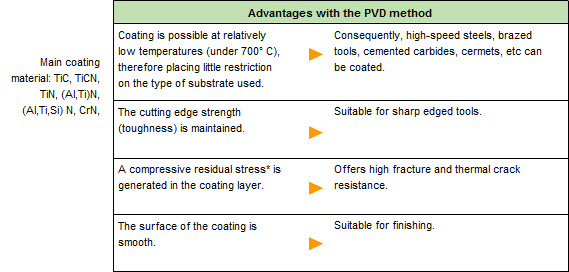

To be able to select a tool grade for a certain machining application it is necessary to understand the differences and features of both the CVD and PVD coating methods.

- Click below to see the advantages and disadvantages of CVD.

Advantages

Disadvantages

Features of PVD Coatings

Coating material and machining performance

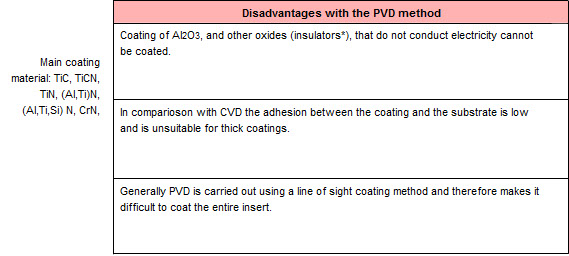

The materials that are used in the PVD coating method include TiN (titanium nitride), (Al, Ti)N (aluminium titanium nitride), (Al,Ti,Si)N (aluminium titanium silicon nitride), CrN (chromium nitride) and amorphous* hard carbon. Additionally TiC and TiCN that are generally used in the CVD process can also be used with the PVD process. Each material has its own specific properties and they can also be used either as single or multi-layers, according to their required use.

- Click on the highlighted headings for more information!

Hardness (Flank wear resistance)

(Al,Ti)N, is a complex nitride of aluminium and titanium. The Al and the Ti particles have different atomic radii creating a distorted microstructure. It is due to this distortion that makes the coating layer hard. An even harder coating layer is that of (Al,Ti,Si)N this is due to the Si particles within the coating layer that provides high flank wear properties.

When comparing (Al,Ti)N, (Al,Ti,Si)N with CrN it can be seen that CrN itself is not a hard particle. However, when machining copper under high cutting temperature conditions the coefficient of friction of CrN is much lower than that of TiN and (Al,Ti)N, therefore offering excellent welding resistance properties. TiN is one of the first generation coating materials, it is harder than cemented carbide and can be used effectively to prolong tool life due to the fact that it is chemically stable under coating end mills for hardened steel milling.

Oxidation temperature (Notching resistance of the end cutting edge / crater wear resistance)

(Al,Ti)N is thermally stable at high temperatures and has excellent wear resistance during high-speed cutting. This is due to the fact that the Al oxidizes under the high temperatures and pressures during machining and forms a protective film of amorphous Al2O3. (Al, Ti, Si)N has even higher thermal stability than (Al,Ti)N and is used for coating end mills for hardened steel milling.

TiN with its high oxidation resistance and low free energy of formation (i.e.thermally stable) is also effective in lengthening tool life.

x

Substrates coated using PVD

Process

Advantages and disadvantages with PVD method

Features of PVD Coatings

x

P.V.D-coated grade

(AI, Ti)N

Carbide substrate

Cross section of the micro-structure