Tool grades

Cermets

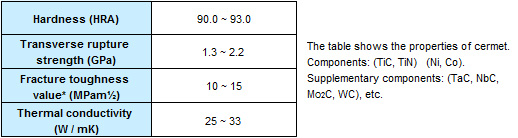

Properties

Cermet is a term that is made up from the words ceramics and metal. Cermet has both the hardness of ceramics and the toughness of metals.

Cermet is made of the same powder elements as cemented carbide is. However unlike the main element of cemented carbide is WC, cermets use titanium carbide (TiC) as the main element. The binder metal used for cermets is nickel (Ni). This is because Ni has higher adhesion strength to TiC than cobalt (Co). Though there are disadvantages with this, one being that the adhesion strength between TiC and Ni is not as strong as it is between WC and Co. Thus the toughness of cermets tends to be weaker than that of cemented carbides. To improve the toughness of cermets, the additions of materials such as molybdenum (Mo), titanium nitride (TiN) and other metal has been introduced. This lead to devlepment of TiC-TiN-Mo-Ni-based cermets that offer improved toughness and is today’s mainstream cermet.

- Click below for more information!

Manufacturing of cermets

Use of cermets

Manufacturing

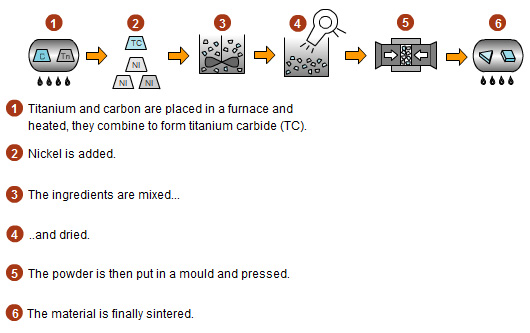

Manufacturing of cermets

Use of cermets

Cermets, if used correctly, can lead to an increase in productivity and product quality. However, if used incorrectly then these benefits will not be achieved.

Suitable machining

Cermets are suitable for the following areas of machining where their superior welding resistance can be fully exploited:

- Finish machining of steel and cast iron where a high quality surface finish is required.

- Machining of steels where the cutting speeds can not be increased.

- When machining mild steel. (Mild steel is prone to welding problems)

Unsuitable machining

Cermets are unsuitable for the following areas of machining because it lacks toughness:

- Large depth of cut, high feed, interrupted machining, etc. This type of machining should be avoided as much as possible.

- Machining of materials which have low thermal conductivity and tend to work harden, such as stainless steel, high manganese steel, heat-resistant and titanium alloys.

- Machining where the cutting edge is vulnerable to chipping, such as machining of hardened steel and the surface scale of cast iron.

x

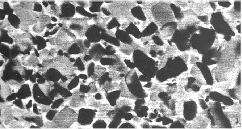

Microstructure of cermet