Tool grades

Micro-grain cemented carbide

Properties

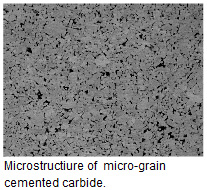

Micro-grain cemented carbide is, as the name explains, cemented carbide that is composed of very fine WC particles. Cemented carbides with WC particles under 1μm in diameter are termed as micro-grain cemented carbides.

In general, the main components are WC-Co cemented carbide with a small amount of VC (vanadium carbide) and Cr3C2 (chromium carbide). The chromium carbide is added as a particle growth inhibitor*. This is to prevent the particles from growing during the sintering process.

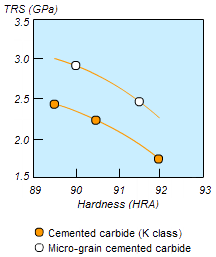

The mechanical properties of micro-grain cemented carbides are high hardness and transverse rupture strength (TRS). The graph tp the right shows a comparison between micro-grain cemented carbide and general cemented carbide. It shows that when micro-grain cemented carbide and general cemented carbide posses the same hardness, the micro-grain cemented carbide has a higher TRS value.

The graph above shows the relationship between hardness - and TRS (transverse rupture strength).

Likewise, if the micro-grain cemented carbide and general cemented carbide have the same TRS value, then the micro-grain cemented carbide is harder than the general cemented carbide. This is all due to the fine grain structure. When the carbide particles are fine, the amount of Co between WC particles becomes less and this improves the plastic deformation resistance (hardness). Additionally as the grains become smaller, crack propagation is inhibited leading to higher fracture resistance (transverse rupture strength).

- Click below for more information!

Use of micro-grain cemented carbide

Use of micro-grain cemented carbide

Micro-grain cemented carbide has superior properties at room temperatures. However problems can be experienced when exposed to high temperatures. For example, when used under conditions where the cutting edge temperature rises drastically then the rate at which crater wear develops will also increase. This is due to the fact that the tool grade is generally a straight version, a WC-Co cemented carbide.

Overall the advantages of micro-grain cemented carbides are the high hardness properties and high TRS value. Additionally due to the small grain size it is possible to manufacture a tool with a sharp edge. Thus, micro-grain cemented carbides are suitable for applications were cutting edge temperatures do not rise significantly and for areas that require a sharp cutting edge and for applications that require both wear and fracture resistance. Micro-grain cemented carbide is commonly used for small diameter end mills because the cutting edge temperatures do not exceed the properties of the tool grade. They are also used for drills that are prone to breakage.

x