![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

The combination of the (Al, Cr, Si) N coating (newly-developed), which has a high oxidation temperature and high lubricity, together with the (Al, Ti, Si) N coating, which has better wear resistance and high adhesion, allows hardened steel with even greater strength to be maintained.

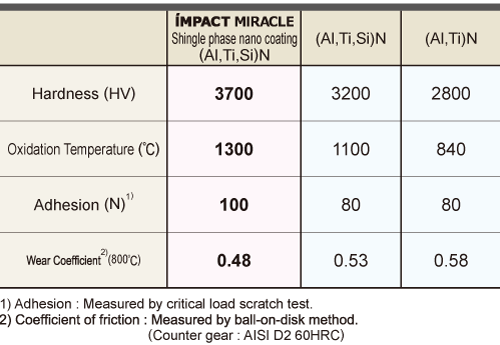

In comparison with the conventional coating single-phase nano crystal coating technology offers higher coating hardness and heat resistance.

When machining hardened steels it can be seen that the IMPACT MIRACLE coating offers a lower friction of coefficient and as such prevents abnormal damage such as chipping.

Our original coating technology enables a multilayer of (Al,Ti)N and (Al,Cr)N. It allows machining of a wide range of workpiece materials.

Newly-developed (Al,Cr)N coating with improved wear resistance.

The smoothening treatment of the coating layer reduces the cutting resistance and improves chip discharge significantly. This next-generation coating offers longer tool life and higher efficiency in machining difficult-to-cut materials.

Mitsubishi Materials and SHINMAYWA INDUSTRIES, LTD. have jointly developed a unique DLC coating that has substantially increased "adhesion strength" compared to previous DLC coating.

The newly developed CVD diamond coated carbide material achieves outstanding abrasion resistance and smoothness due to a proprietary fine multilayer diamond crystal control technology. Suitable for cutting hard brittle materials such as cemented carbide.

Owing to Mitsubishi’s unique plasma chemical vapor deposition (CVD) coating technology, great combination of coating hardness similar to that of natural diamond has been combined with a good adhesion to carbide substrates.

DF end mill series suitable for graphite machining.

Violet coating is the name of the technology of successfully applying a Miracle type coating to HSS substrate tools. The newly developed technology of applying (Al,Ti)N coating at the low temperatures required for HSS substrates, means that Violet coating has the same level of adhesion strength as Miracle coating. Additionally high film hardness and excellent oxidation resistance properties have also been realised.

Technical consultation from here

24/7Contact form Japan

Japan  Japan

Japan  United States

United States  Mexico

Mexico  Brazil

Brazil  EU

EU  United Kingdom

United Kingdom  Germany

Germany  Spain

Spain  France

France  Italy

Italy  Poland

Poland  Turkey

Turkey  Czechia

Czechia  China

China  Asia Pacific

Asia Pacific  Thailand

Thailand  Vietnam

Vietnam  Indonesia

Indonesia  India

India ![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

![]() For finish cutting

For finish cutting

![]() For medium cutting

For medium cutting

![]() For rough cutting

For rough cutting