![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

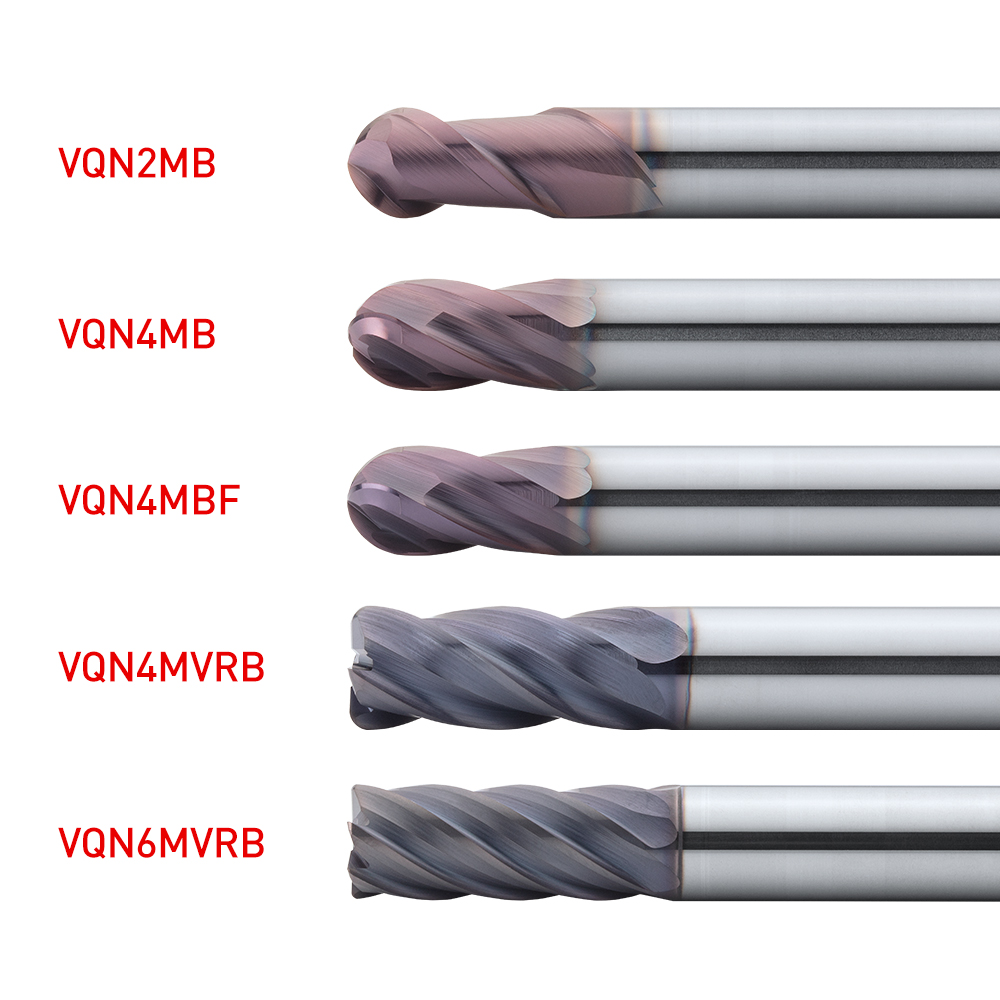

The already successfully established VQ series of high-performance end mills from Mitsubishi Materials is now even more flexible and versatile, thanks to the new VQN versions. The new VQN4 / VQN6MVRB corner radius end mills as well as the VQN2MB, VQN4MB, VQN4MBF ball nose end mills offer excellent wear resistance and coating adhesion when machining Ni-based superalloys. The adapted number of cutting edges depending on the diameter guarantees stable and efficient machining even for complex applications and workpiece shapes.

Compared to the conventional VQ end mill series, which is equipped with an (Al, Cr)N coating, the VQN range expansion has been equipped with a new and next generation (Al, Ti, Si)-based coating. The use of this coating in combination with the adapted substrate and special flute geometry enables significantly improved wear resistance and reliability when machining Ni-based materials. Likewise, the surface of the coating is subjected to additional smoothing and thus offers better surface qualities with reduced cutting resistance as well as providing optimised chip removal.