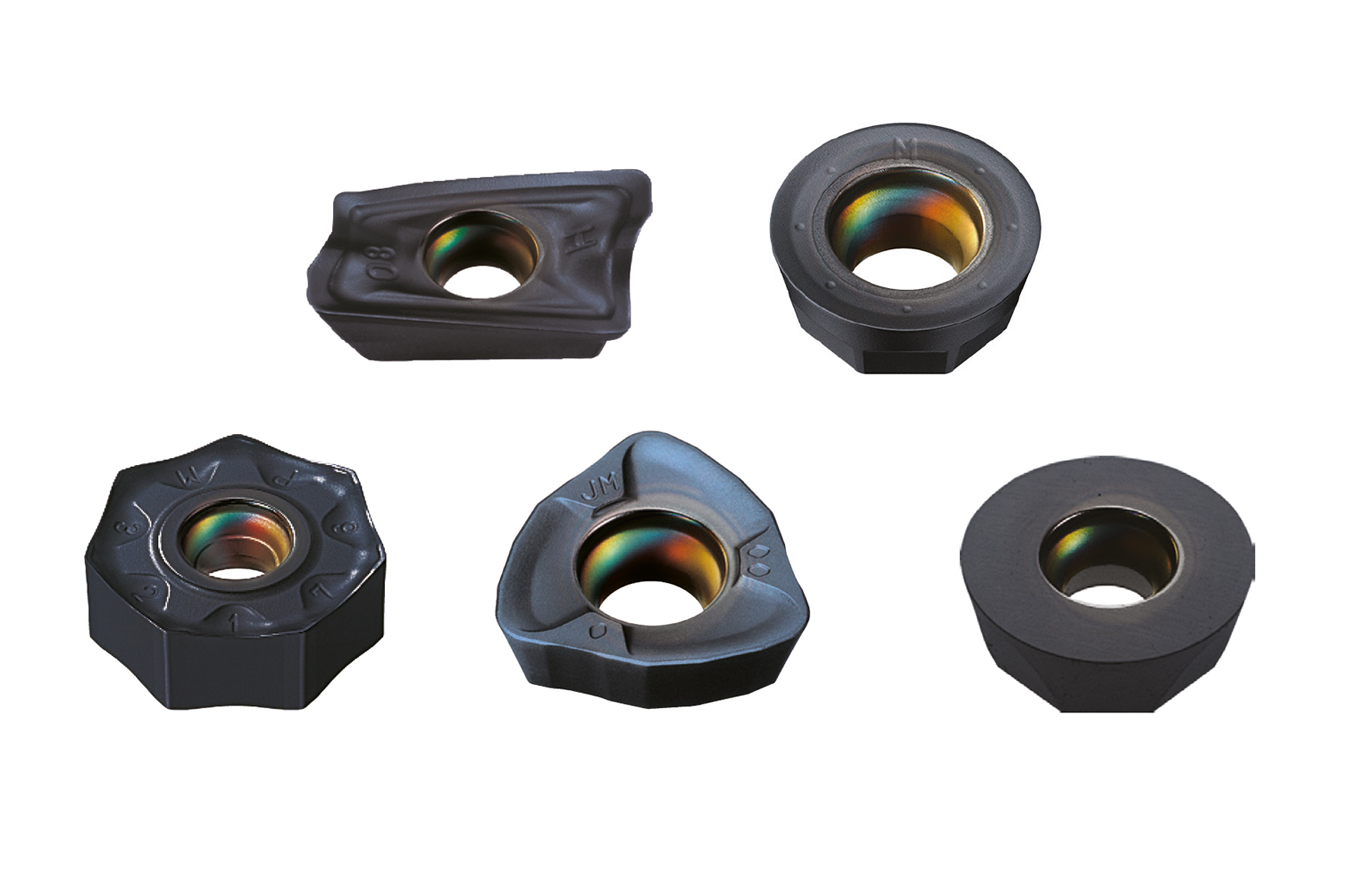

MMC Hartmetall GmbH and MMC Hardmetal Europe (Holdings) GmbH Announce Strategic Merger under the Mitsubishi Materials Name

Meerbusch Germany, September 1st, 2025 - MMC Hartmetall GmbH and MMC Hardmetal Europe (Holdings) GmbH announced their official merger and renaming as of September 1st, 2025. This consolidation marks a significant milestone in Mitsubishi Materials Corporation’s continued growth and alignment of its European operations under one unified identity.

Japan

Japan  United States

United States  Mexico

Mexico  Brazil

Brazil  EU

EU  United Kingdom

United Kingdom  Germany

Germany  Spain

Spain  France

France  Italy

Italy  Poland

Poland  Turkey

Turkey  Czechia

Czechia  China

China  Asia Pacific

Asia Pacific  Vietnam

Vietnam  Indonesia

Indonesia  India

India