![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

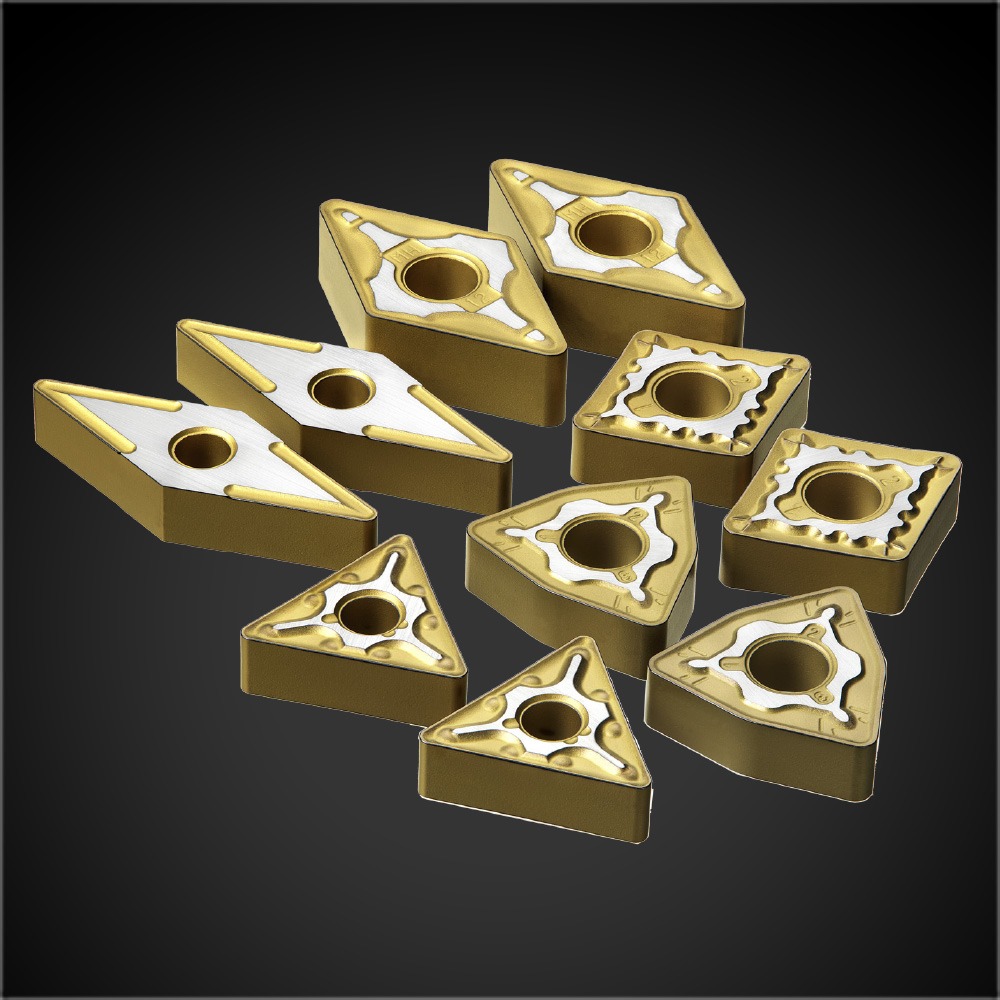

Introducing the new MC6125 grade, a comprehensive range of inserts that becomes the first choice for the high-performance and reliability when turning a wide range of carbon and alloy steels.

MC6125 is a general purpose carbide grade with state-of-the-art CVD coating for super efficient machining of steels.

MC6115