Série GW

Sistema para corte e canal

Long Lasting, Easy to Use Cutting Off & Grooving System

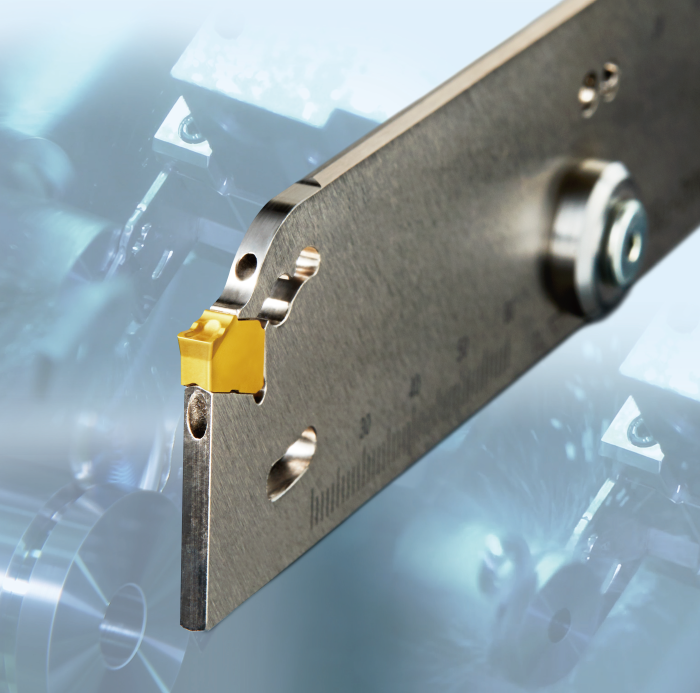

Clamp Mechanism

Simple insert clamping method offering high rigidity.

To prevent the insert from being pulled out during machining a reverse taper angle has been designed from the front of the insert, additionally the design also includes 3 large locating faces between the insert and the blade offering increased cutting edge reliability. The blade itself is made from a special alloy steel to suit this application. In respect to insert indexing a unique wrench is supplied to ensure ease when changing the insert.

Highly Reliable Insert Clamping

Easy Insert Indexing

The inserts can be indexed easily with a one action movement of the wrench.

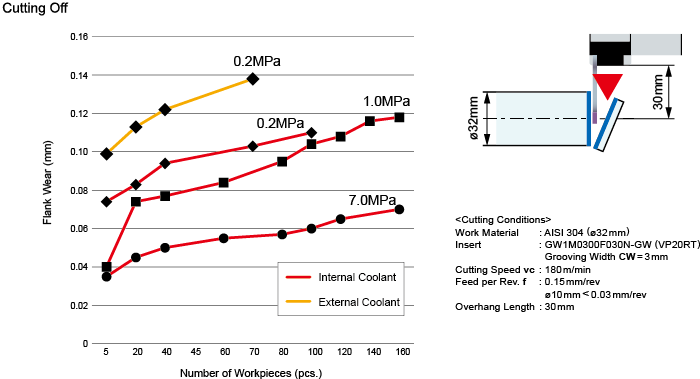

Internal Coolant

Increased wear resistance due to the use of 2 through coolant ejection holes.

2 through coolant holes supply the coolant to both the rake and flank face, leading to effective cutting edge cooling and increased wear resistance.

Additionally this blade can also be used for both low pressure and high pressure coolant (7MPa).

Developer's Voice

How is it possible to reduce heat generation?

The 2 coolant holes used in the blade are capable of using high coolant pressures of up (7MPa), this is achieved by using as large as possible a through coolant hole diameter. The ejection holes are located close to the cutting edge so as to improve the cutting edge cooling effect and increasing wear resistance.

Suitable for Various Set Ups Improving Tool Handling

Effects of Through Coolant

Flexible set up possible with the use of 6 coolant ports.

There are 6 coolant ports designed into the tool block. This makes it easier for the end user to set up the tool block and blade to a configuration that suits their needs. If necessary it is also possible to use coolant hose. The ejection type coolant also improves cutting edge cooling and chip evacuation.

Chip Breaker

Breaker System Offering Excellent Chip Disposal Properties

Cutting Performance

Cutting Off of Alloy Steel (AISI 4140)

No abnormal cutting edge damage, possible to extend tool life.

Cutting Off of Stainless Steel (AISI 304)

No abnormal cutting edge damage, 4 time longer tool life was achieved.

Application Examples

The examples shown are actual applications and can differ from the recommended cutting conditions.

Fale conosco

Formulário para contato Japão

Japão  Estados Unidos

Estados Unidos  México

México  Brasil

Brasil  EU

EU  Reino Unido

Reino Unido  Alemanha

Alemanha  Espanha

Espanha  França

França  Itália

Itália  Polônia

Polônia  Turquia

Turquia  Tchéquia

Tchéquia  China

China  Asia Pacific

Asia Pacific  Vietnã

Vietnã  Indonésia

Indonésia  Índia

Índia