Alimaster

For high productivity machining of aluminium alloys

High Efficiency. Multi-functional Machining of Aluminium Alloys

Feature

High Efficiency & Economy DLC Coating

By adopting a unique DLC coating with excellent adhesion and welding resistance, cutting friction is reduced thereby provides extra stability and efficiency. Additionally wet or dry cutting is possible for slot milling and contouring.

DLC coatings may differ naturally in colour. This has no effect on quality or performance.

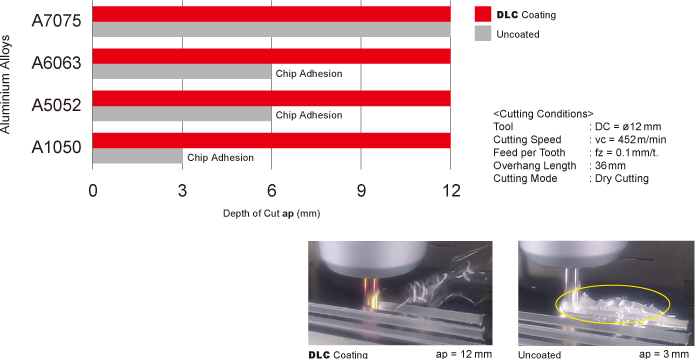

Dry Slot Milling - Comparison when Machining Different Materials

The excellent welding resistance and chip evacuation properties enables high efficiency slot milling even at large depths of cut.

* Air blow both internal and external is used to effectively evacuate chips.

Cutting Performance

With DLC Coating - Example of Dry Machining A7075 Material

Multi-functional dry machining is possible.

Uncoated Type - Slot Machining A7050 Material

Utilising internal coolant and optimised cutting edge geometry enables double the efficiency levels of conventional products.

Uncoated Type - Plunge Machining A7050 Material

Higher feed rates than conventional products brings greater machining efficiencies.

Cutting Example

Machining with a High-speed, High-output Horizontal 5-axis Machining Centre

Ultra-high efficiency processing was achieved with a stable chip discharge and no chattering.

Metal Removal Rate of 10,000 cm³/min.

Technical consultation from here

24/7Contact form

Japan

Japan  United States

United States  Mexico

Mexico  Brazil

Brazil  EU

EU  United Kingdom

United Kingdom  Germany

Germany  Spain

Spain  France

France  Italy

Italy  Poland

Poland  Turkey

Turkey  Czechia

Czechia  China

China  Asia Pacific

Asia Pacific  Vietnam

Vietnam  Indonesia

Indonesia  India

India