High Feed Radius Milling Cutter

AJX

Cost Reduction with ultra high feed milling over a wide range of applications!

Features

Ultra High Feed Cutting

Employing a two-step straight cutting edge to form the lead angle α and β with a wiper edge, the AJX can achieve an extra high feed rate of up to 3.5mm/tooth for ultimate efficiency in rough machining.

High Reliability Cutter Body

Triangular insert shape is ideal for safe multi-functional milling

Selection Reference Table ( Cutting Edge Count and Cutting Conditions)

<Cutting Conditions> Workpiece Material: SCM440, Insert Grade: FH7020, Cutting Speed: 150 m / min. Protrusion amount is calculated based on the maximum value in the table for recommended conditions. Rounded down to the last two digits.

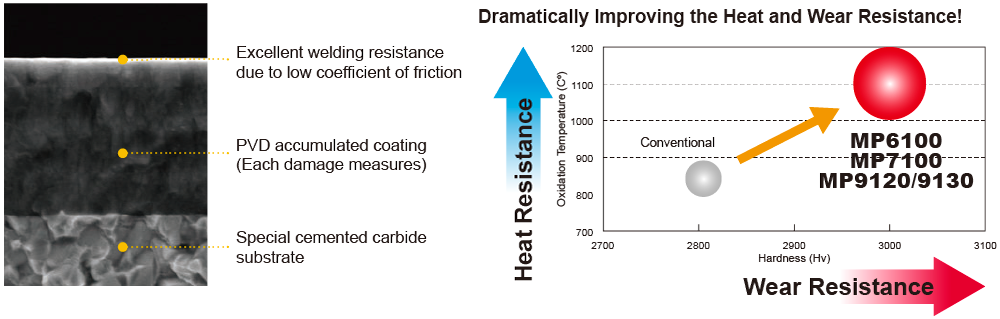

PVD Coated Grade for Difficult-to-cut Materials

MP9140

MP9140 Has Excellent Welding Resistance Due to Smoothened Surface

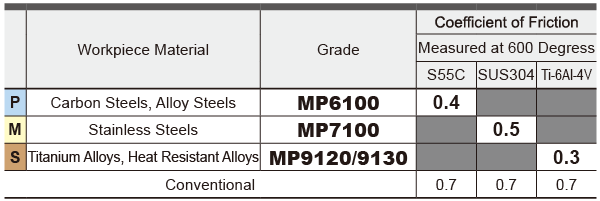

Insert Grades for a Wide Range of Materials

Al-Ti-Cr-N base PVD Accumulated Coating

Excellent welding resistance due to low coefficient friction!

TOUGH-Σ Technology

A fusion of the separate coating technologies; PVD and multilayering realises extra toughness.

PVD accumulated coating

Wide Selection of Inserts

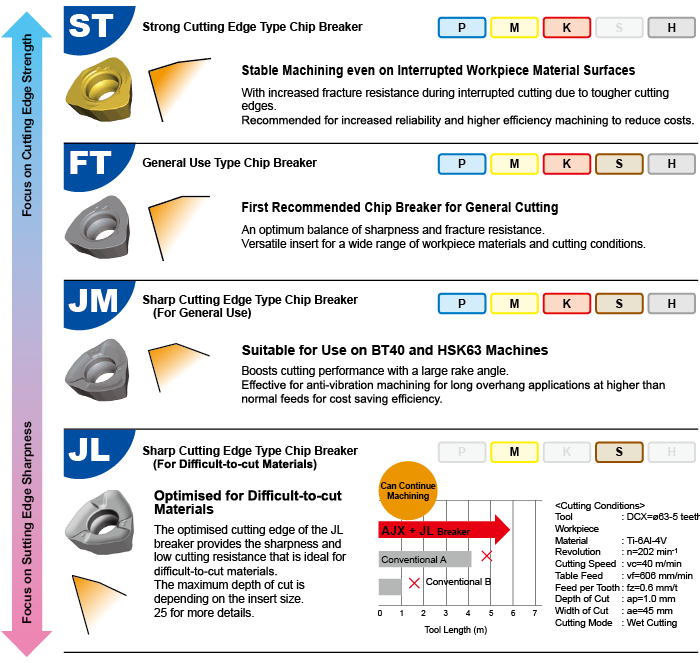

Cutting Performance

General Steel Machining

MP6120 Provides Superior Resistance to Thermal Cracking and Welding

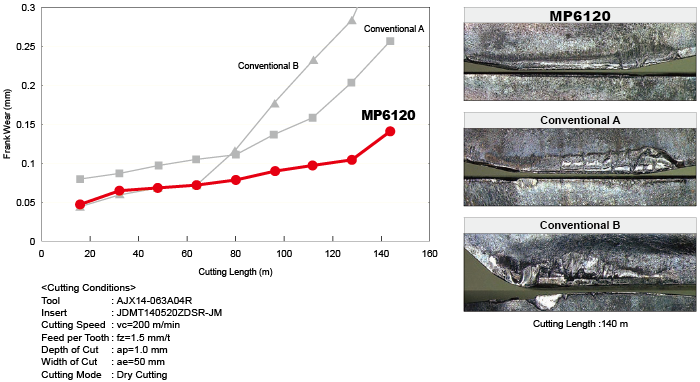

Comparison of Fracture Resistance by Titanium Alloy Machining.

MP9140 achieved triple more tool life than conventional product B.

Application Examples

Technical consultation from here

24/7Contact form

Japan

Japan  United States

United States  Mexico

Mexico  Brazil

Brazil  EU

EU  United Kingdom

United Kingdom  Germany

Germany  Spain

Spain  France

France  Italy

Italy  Poland

Poland  Turkey

Turkey  Czechia

Czechia  China

China  Asia Pacific

Asia Pacific  Vietnam

Vietnam  Indonesia

Indonesia  India

India